Heavy

PK 880 TEC

- Go back

- Home

- Products

- Loader Cranes

- Models

- PK 880 TEC

PK 880 TEC

PRECISION AND PERFORMANCE REDEFINED

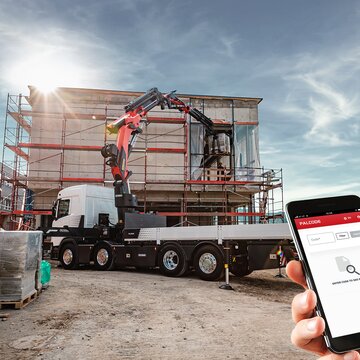

The new PK 880 TEC stands out with its advanced design, cutting-edge technology, and peak precision. Its impressive lifting capacity and smart assistance systems push it beyond its performance class, making it the ideal solution for demanding applications.

Enhanced efficiency: SLEWING LOCK prevents crane movement within a predefined restricted area, helping to eliminate risks in dangerous zones. The MEMORY POSITION saves up to four crane positions, enabling fast, repetitive operations with maximum accuracy. The LEVELING ASSISTANT significantly reduces the time required to level the vehicle, ensuring optimal working conditions.

A new LIGHTING SYSTEM, featuring two work lights on the crane and fly jib, as well as LED strips under the knuckle boom, significantly improves visibility of the load and surroundings − ensuring maximum safety, even in low-light conditions.

With intelligent, high-performance features and top-tier precision, the PK 880 TEC sets new standards in efficiency and operator comfort.

- More intelligent operation with PALTRONIC 180 control electronics

- Extra smooth control thanks to LX-6 control valve

- Very stiff and light boom system thanks to P-Profile

- More efficient and faster due to continuous slewing system

- More efficiency with fly jib due to DPS-C

- Maximum utilisation of the working range thanks to extended HPSC

- More lifting power due to S-HPLS

- Practical and attractive due to Functional Design

Height and Bound

Smart height and workspace limitation at the touch of a button

With HEIGHT & BOUND you configure the crane once and then work worry-free beneath overhead obstacles or inside confined sites. The assistance system simultaneously limits the maximum working height and, by means of a “virtual wall”, the permitted lateral and vertical workspace.

Memory Position

Save up to 4 crane positions with the Memory Position and return to them again and again with only 2 levers.

Leveling Assistant

The Leveling Assistant supports the crane operator during the stabilizing process by leveling the vehicle efficiently with just one lever movement on the Radio Remote Control P6 or P7.

Smart Control

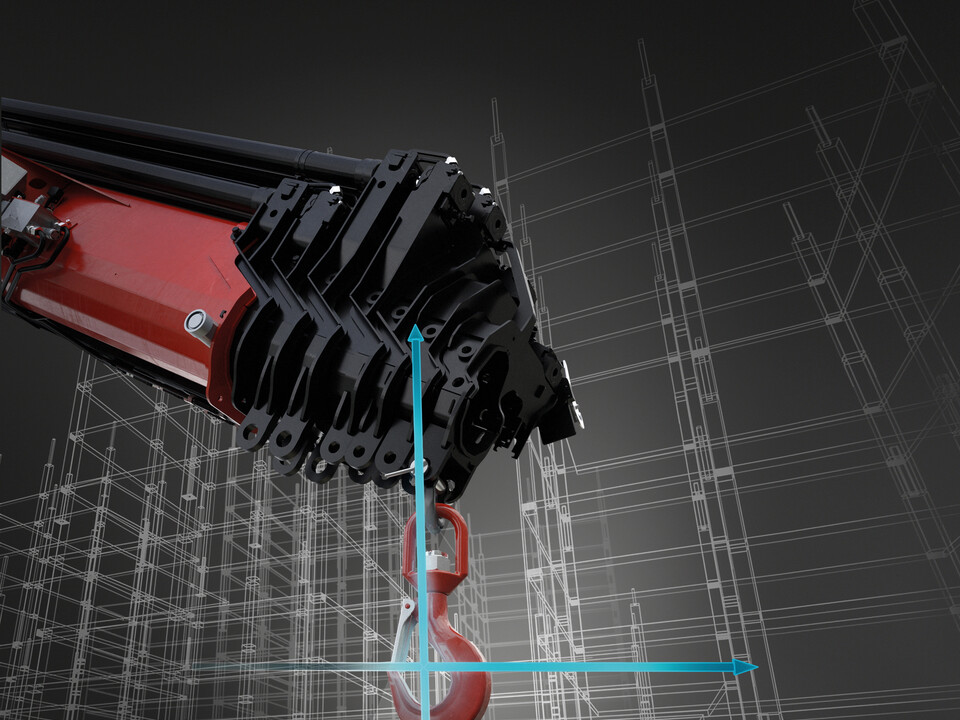

With Smart Control, the operator of a TEC crane turns hard work into smart work and can control a horizontal or vertical movement of the crane tip with only one lever. The intuitive control of the tip allows a diagonal movement as well as any curve by combining both directions.

P-Profile

The polygonal or drop-shaped P-Profile is especially rigid and simultaneously light weight design perfection. Thanks to self-lubricating materials, the extension boom system is low in maintenance.

Lane Lock

Maximum Safety – The new LANE LOCK feature for your loader crane

Effectively prevent unwanted slewing into dangerous areas such as oncoming traffic or other hazardous zones with the innovative LANE LOCK assistance function. Use the menu to activate a preset lock that reliably limits your loader crane‘s slewing range. Thanks to flexible adaptation to your vehicle‘s design and easy operation, you maintain full control at all times – for enhanced safety and precision on every job site.

Slewing Lock

Custom locking zones – Limitation with the new SLEWING LOCK function

Maintain full control over your loader crane and specifically block unauthorized slewing areas. With the SLEWING LOCK function, you can set custom angles to safely block dangerous zones. Simply define two points via the remote control to set the restricted area – for maximum control and safety, no matter where your vehicle is positioned.

PALTRONIC 180

The PALTRONIC 180 is the most advanced control electronics for our loader cranes, enabling a safe, precise, and reliable operation. With its state-of-the-art technology, it allows for a variety of innovative assistance systems, such as Memory Position or the Leveling Assistant, and sets the standard for the new TEC generation.

CONTROL VALVE LX-6

The innovative control valve LX-6 enables particularly precise control of the new TEC-range. In combination with our specially developed PALcom P7 radio remote control, this gives the crane operator the best control over the TEC loader crane. As a result, every movement is even more precise and, above all, faster than ever before.

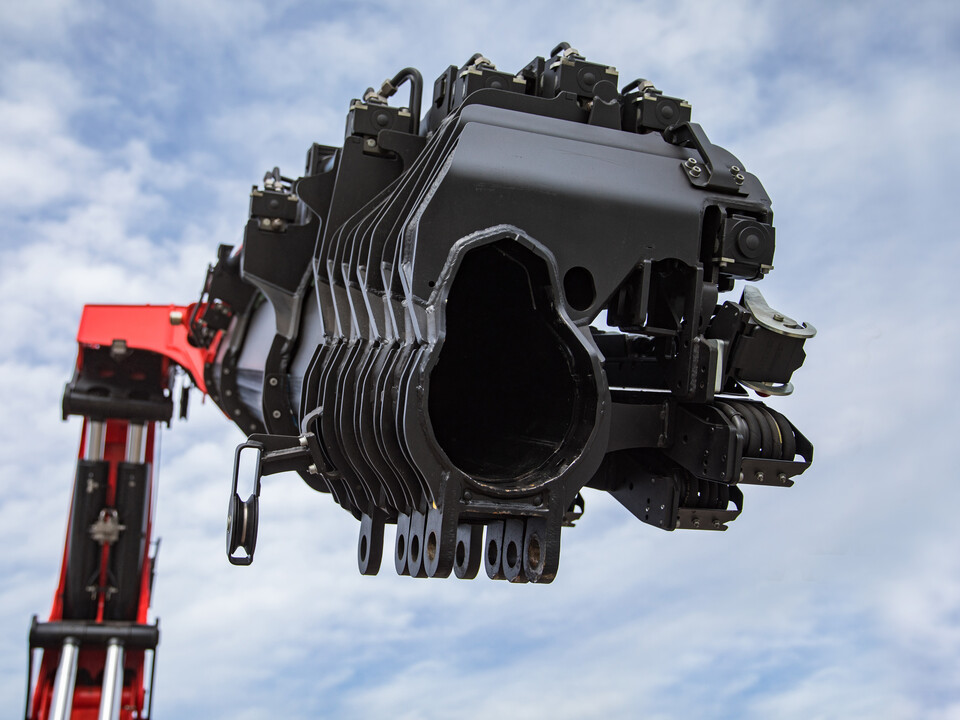

SRC

The SRC (Synchronised Rope Control) system maintains a constant distance between the pulley head and the hook block. This advantage is particularly valuable in terms of ease of use for the operator. Moreover, the efficiency of any operation is noticeably improved.

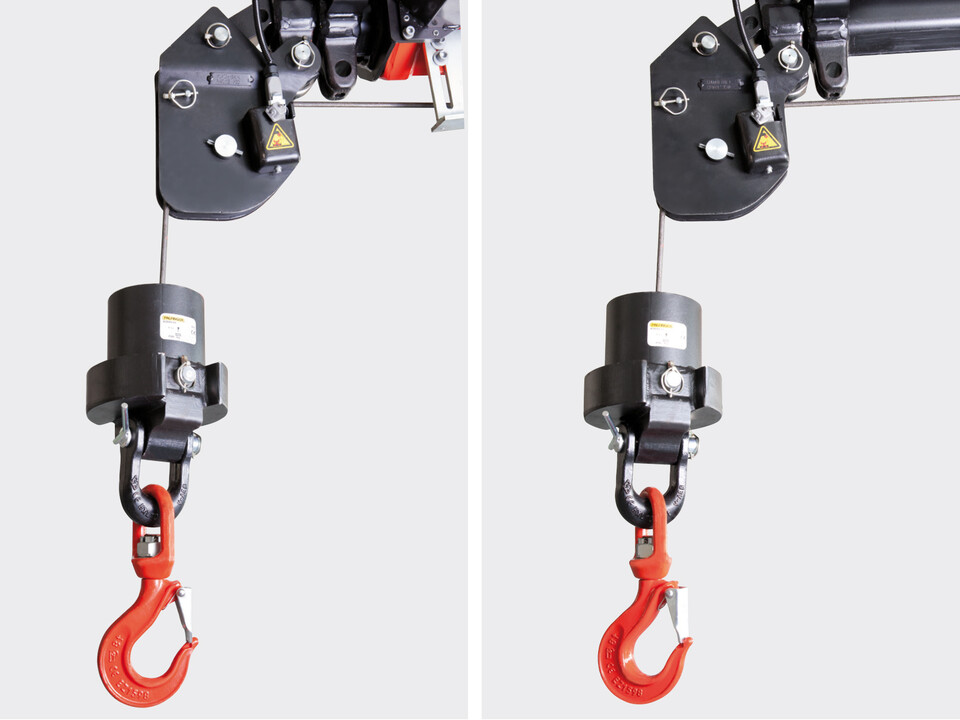

RTC

The new RTC (Rope Tension Control) system is an automatic rope tensioning device that helps to fold and unfold the crane. This is a further innovation from PALFINGER that will significantly shorten the set-up time.

Experience the product features

AOS

PRODUCT FEATURES

The patented PALFINGER "AOS" oscillation suppression system cancels out vibrations and blows that occur during crane operation. Any "post-oscillation" is prevented through rapid braking or load changes. The result is a decisive increase to safety in crane operation for employees, the load and building.

HOW IT WORKS

The electronics receive signals from pressure sensors on both sides of the elevating cylinder and interpret them as arm vibrations. The signals for the counter-movement of the elevating cylinder are handled by the control valve. The incurred vibration can be cancelled through the exactly determined frequency and wavelength. The result is damping of the arm to just one or two short vibrations so that the arm comes to an immediate standstill.

* Optional feature/country-specific-equipment

HPSC

PRODUCT FEATURES

The High Performance Stability Control (HPSC) is a fully proportional system for monitoring the stability of the crane vehicle. Sensors for proportional path measurement in the stabilizer supports permit completely variable support positioning. Hence, the permissible, safe working range can be calculated for any support situation.

HOW IT WORKS

The HPSC system calculates the permissible working range for any slewing angle of the boom system and for any support situation. The position of the stabilizer support is detected by means of a cable extension transducer or magnetostrictive position sensor. Based on the intelligent calculation algorithm developed by PALFINGER, it works more efficiently than comparable systems that are available in the market.

HPSC Plus

PALFINGER has continued development of the well-proven stability control system HPSC and is offering additional application-orientated functions in a modular system. Three modules which are available on their own as well as combined, turn HPSC into HPSC-Plus. In this way, the stability control system can be adapted to the current situation and ensure an optimal performance.

* Optional feature/country-specific-equipment

P-Fold

P-Fold is a comforable PALFINGER assistance system. It makes folding and unfolding an easy job for the operator. The P-Fold system also works in combination with the innovative RTC (Rope Tension Control). Both systems perfectly support the crane’s set-up processes and thus reduce set-up times to a minimum. The operator will be guided safe and clearly thanks to the intuitive menu navigation of the new PALcom P7 – a major benefit also for inexperienced operators. In addition to the significant increase in operator comfort, the prevention of damage on vehicle, load and rope is another important point.

* Optional feature/country-specific-equipment

| Max. lifting moment | 82.8 mt |

| Max. lifting capacity | 25000 kg |

| Max. hydraulic outreach | 21.7 m |

| Slewing angle | ∞ |

| Slewing torque with 2 gears | 8.4 mt |

| Stabilizer spread (std) | 8.6 m |

| Fitting space required (std) | 1.64 m |

| Width folded | 2.55 m |

| Max. operating pressure | 385 bar |

| Pump capacity | 100 - 130 l/min |

| Dead weight (std) | 7160 kg |

Cranes shown in the leaflet are partially optional equipped and do not always correspond to the standard version.

Country-specific regulations must be observed. Dimensions may vary. Subject to technical changes, errors and translation mistakes.

|

|

|

|

|

|

|

|

|

|

|

|

|---|---|---|---|---|---|---|---|---|---|---|

| C | 82.8 | 10.9 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 7160 | 2505 | 2550 | 1640 |

| D | 78.6 | 12.9 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 7450 | 2505 | 2550 | 1640 |

| E | 77.8 | 15.0 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 7740 | 2505 | 2550 | 1720 |

| F | 76.2 | 17.2 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 8010 | 2505 | 2550 | 1720 |

| G | 75.5 | 19.5 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 8250 | 2505 | 2550 | 1820 |

| H | 75.0 | 21.7 | ∞ | 8.4 mt | 38.5 | 100 - 130 l/min | 8450 | 2505 | 2550 | 1820 |

The outreaches stated are with a boom angle of 20° and are therefore not the maximum. When using mechanical boom extensions, the loads shown on the charts need to be reduced by the weight of these extensions.

PALFINGER SERVICES

Brochures

You are currently on the PALFINGER Europe page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?