Comfort, support, efficiency and safety

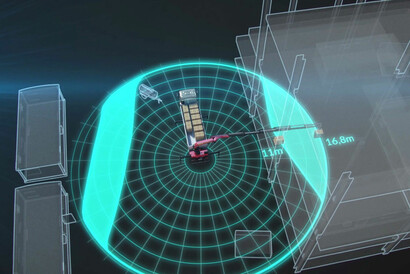

Digital solutions from PALFINGER make work processes easier and working with its products even more comfortable. In this context, the focus is as much on physical driver comfort as on integrated and user-oriented systems that increase user-friendliness and safety. New assistance systems make handling easier and reduce initial training time on the device. The new visualisation and control systems enable users to remain outside of the danger area during utilisation. PALFINGER fleet management solutions provide an improved overview of device use, while integrated communication systems optimise data exchange between fleet managers and crane operators. This improves the reliability of device use planning and reduces time-consuming, manual coordination and administration activities. A key topic when it comes to support solutions is preventive maintenance, which helps to prevent expensive repairs and maximises device uptime.