- Home

- Products

- Hookloader and Skiploader

- Highlights

Hookloader & Skiploader Highlights

V Drive, the new cab control

At the cutting edge of controller technology, the V DRIVE offers intuitive day-to-day operations. The versatility of the screen allows to manage all your options, connected systems and accessories from a single controller. Benefit from all functionalities in a compact and ergonomic item with a smart design.

With 5 screens and dozen of possibilities to adapt the icons to the exact functions, the V Drive cab controller is the most complete and flexible tool of our offer. Its intelligent conception ensures its ability to remain up to date and ready for future changes in requirements and the addition of new functionalities.

Noise or safety, why should you choose?

Whether it's to keep a sleepy street quiet or to reduce the sound level of a noisy site, the new "Silent mode" option can improve working conditions while maintaining a high level of safety.

When the option is activated, the traditional buzzer is replaced by three flashing lights to warn of possible arm movement. The lights are strategically placed around the hookloader for maximum visibility: one at the front and two at the rear. The safety of the work site is preserved and the operator handles the containers in better conditions.

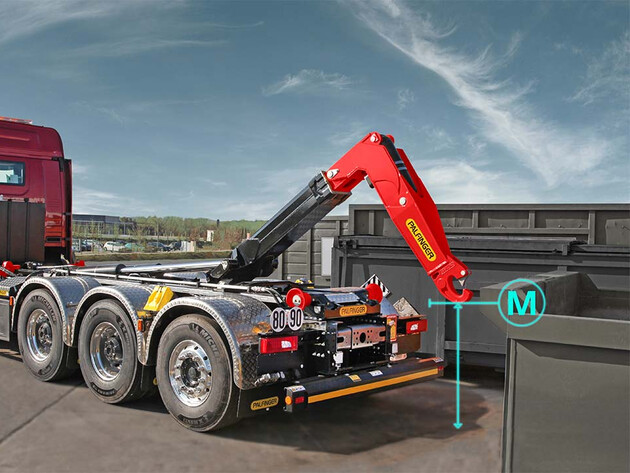

Control your PALFINGER hookloader with ease

Whether it's unloading, loading or tipping, the automatic sequence control of the PALFINGER hooklift performs all the necessary hydraulic functions automatically one after the other.

Simply select the function, operate the joystick and the work cycle is complete. The movements of the underride protection, the hydraulic inner lock, the arm, the tipping cylinder and the optional functions such as axle stabilizers or the front body safety device are now carried out autonomously in the planned sequence.

All you have to do is monitor the process.

PALFINGER CONNECTED

Efficiency for fleet, truck and hookloader - we support you in modern fleet management with efficient digital platforms, optimzied for fleet managers, operators and service partners.

Time saver – Advanced Rapid Motion

The advanced rapid motion option increases the performance and saves time during container handling. More daily rotations are possible with less dead time and drivers avoid blocking the location for longer than necessary. It reduces the cycle time by enabling high speed operation while extending (-50%) and retracting (-30%) cylinders.

POP - PALFINGER Origin Protection

The main components are sand-blasted, degreased, primer painted and final coated (according to customer specification) before assembling, all other parts are zinc nickel anticorrosion treated (meets ISO 12944 standard specifications concerning surface protection, classification 3).

SAM - Secured Advanced Mounting

PALFINGER offers corrosion protected and fully boltable mounting plates and accessories