Meet the winners of PALFINGER's #reachanything Operator Challenge: Steve Connally and Neal Smith! These two lucky individuals just returned from the PALFINGER headquarters in Austria and had some stories to tell. Read on to learn all about their week in Austria!

Tell us about yourself and your company.

Adaptable Aerial Solutions, LLC. (AAS) provides mechanized tree removal to a multi-state market-based in Eastern Virginia. AAS Specializes in hazardous technical tree removal and risk mitigation. I am a retired Captain with Norfolk Fire Rescue and a retired Virginia Paramedic. I’ve been a tree climber for over 25 years and an Arborist for over 20. I am an active instructor/trainer in various subspecialties of the Arboriculture Industry, including crane use in Arboriculture.

How many years have you been in business?

Five.

What does an average day on the job look like?

I am 100% a subcontractor, so generally, I deal with trees the primary contractor feels would be safer or more efficient to be removed through mechanization with the knuckle boom. It may be a single dead tree with hazards underneath it or a risk to life safety by climbing it and rigging it down manually. The job site may have so many obstacles on the ground, it would be more efficient to let the crane strategically place pieces in a spot for processing or there may be so many trees, the crane simply provides force multiplication in order to maximize productivity in the allotted timeframe.

What challenges do you face?

There are always challenges working in residential and commercial settings where you cannot directly predict and control the setup location of the crane, the drop zone challenges, and the obstacles you have to work around. The structure of the tree or the condition of it present[s] unique challenges. Working in a space where you have to work around, under, and next to obstacles in the tree present a unique opportunity to grow as an operator. Working with weights that are calculable within reason but not known are a big challenge.

Tell us about your experience with your knuckle boom crane.

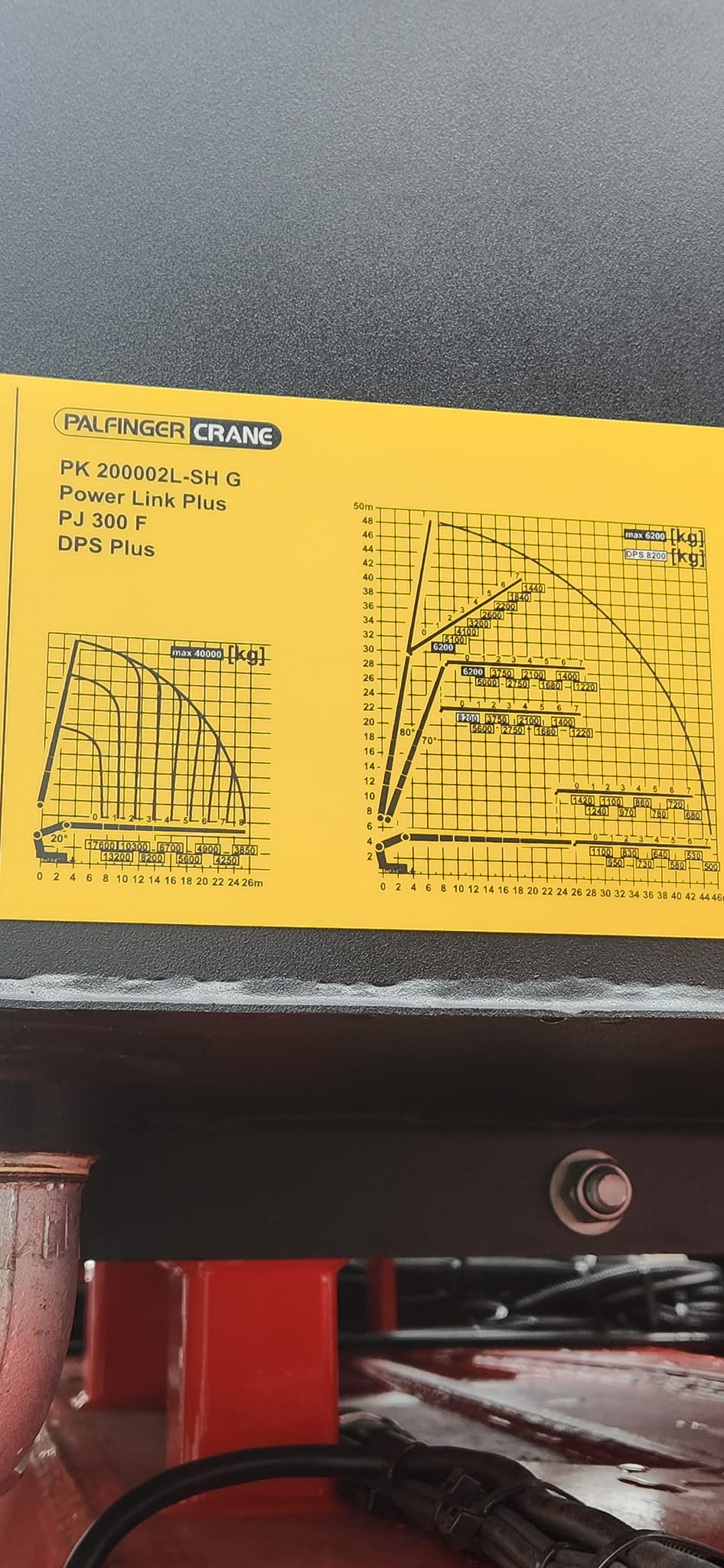

This is my second PALFINGER product. Both my trucks are custom-built for my business application. I have over 5000 hours operating a PALFINGER crane and have found the ease of operation, functionality, and features to be ideal for what I do. The maintenance is user-friendly, the service partner support is outstanding, and the operations are truly functional. Once [the] technique is learned, the ease and simplicity of the operations really help the operator accomplish the job tasks without overly complicating the operation.

What is your favorite part of your knuckle boom crane?

Difficult question. If I had to pick one detail, it would be the HPSC program. Many times I’m faced with a challenging setup for the crane, so being able to have a load chart based on various stabilizer spreads is critical to executing a safe operation.

What is your favorite thing about PALFINGER?

End user support and ease of maintenance. There are always parts available and technical assistance [is] a phone call away.

What is your favorite thing about your trip to Austria?

It’s really difficult to pick one aspect of the trip that was my favorite. So many things come to mind, from the factory to the Mountains and Lakes tour. A fantastic dinner out in town and the time spent with the other operators and the PALFINGER team members was most memorable. So many wonderful experiences. I will say the most beneficial to me was the opportunity to meet and talk to the PALFINGER team members about my product, training, maintenance and operations. Being able to discuss specific technical questions was essential to my trip. The development of these resources and relationships directly affect how I operate and my understanding of my equipment. I had already registered for Paldesk as I stumbled across it one day. Being able to see the functions and resources on my specific unit as well as the additional apps on the portal, are such a fantastic resource for the end user.

Day 1

After about 17 hours [of] travel I was glad to be in Salzburg. Multiple overnight flights and a long and exciting ride from Munich was an exhausting beginning to a fantastic week. On day 1, I arrived at the hotel. After checking into this cool little hotel and receiving the gift bag from PALFINGER, I decided to get some rest. Unsuccessful at an attempt at a nap, I decided to get up and start my adventure. The PALFINGER backpack contained a down jacket, umbrella, ballcap, t-shirt, map and tour passport. Everything was marked carefully with the PALFINGER logo. After evaluating my swag, I decided to go out and take a walk in Salzburg. This old European city had the cobblestone streets lined with shops, cafes, and restaurants. Historic buildings were abound, and the Monastery and Castle overlooked the City. I spent some time exploring and then back to the hotel to get ready for the welcome dinner. All the challenge winners met in the hotel lobby with the PALFINGER team and had introductions. The winners were made up of 2 of us from the US. 2 from Brazil, 1 from China, 1 from Germany, and 1 from Belgium. We spent some time getting to know each other then walked as a group to the Imlauer Sky Restaurant. We were met by members of the PALFINGER corporate team as well as the Sales Team. Each of us enjoyed an amazing meal on the rooftop of this iconic spot with a breathtaking view of the city and mountains. Lots of conversations ensued despite all the travelers being absolutely exhausted. It was a great time, and I’m confident everyone enjoyed themselves. After dinner, we all went back to the hotel and called it a night.

Day 2 Lengau Factory Tour

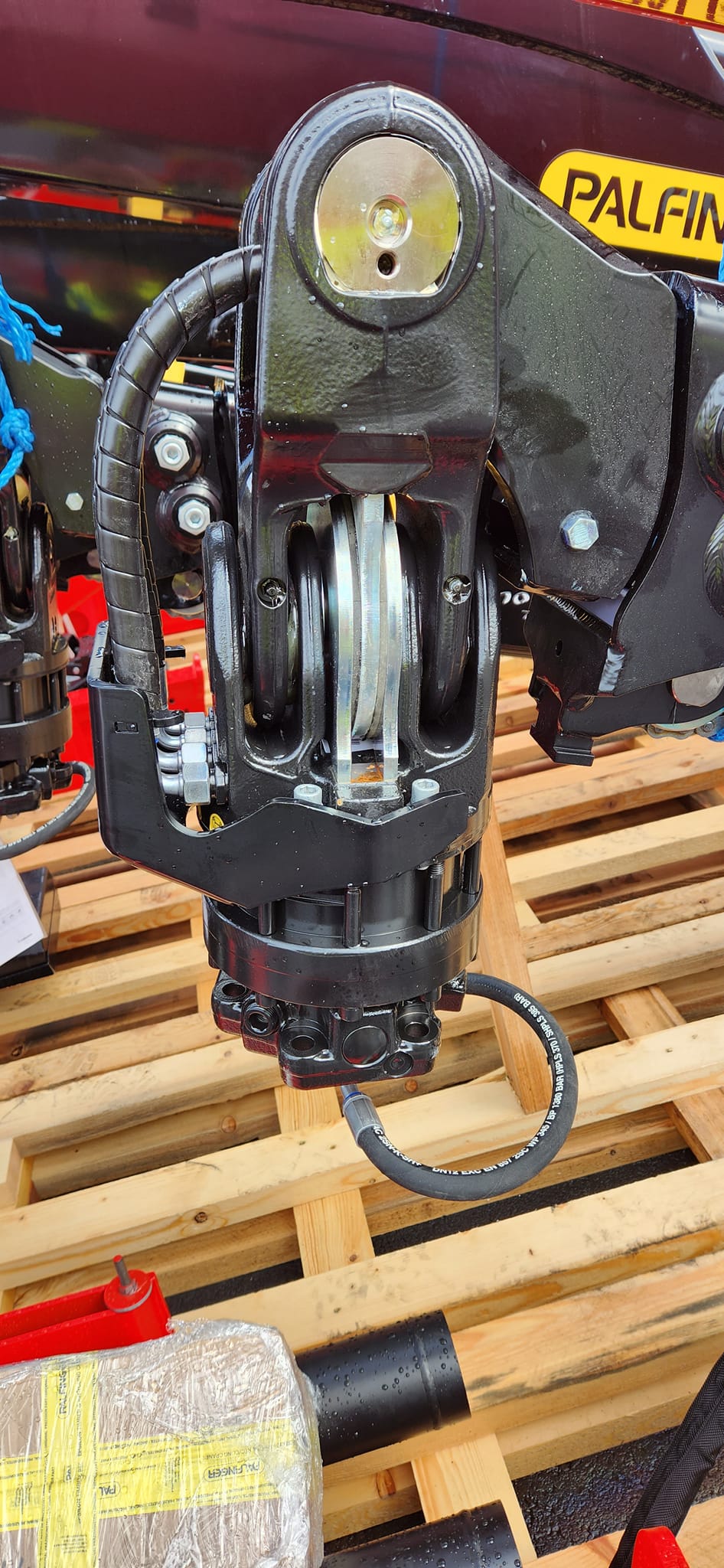

We all met in the lobby and traveled as a group to our VIP Experience at the new, unopened PALFINGER World. We started with some welcome pictures and introductions, then a tour of the facilities. We were able to experience the first group tour of the PALFINGER World, where we learned more about the company history, the global markets, locations of facilities, supply chain and organizations, financial progress of the company and the team members making up the company. We learned about the constantly changing mission and vision, the progress of technology, and the variety of equipment solutions PALFINGER provides to the various industries in the world. We were able to try out hands at VR and simulated operations of cranes, loaders, work platforms, and ocean-based equipment. It was really an amazing opportunity and a great learning experience. After lunch, we were provided a tour of the factory. Our narrated tour took us through the entire factory, from the receipt and organization of the steel used to build to the assembly of the booms themselves. The organization and complexity of the operation is indescribable. Just the explanation of the spare parts being sorted for shipping could fill this page by itself. The automation of the selection and sorting was impressive. We finished the tour in the testing center and assembly of a few factory-assembled trucks. There were a couple cranes being built that I found to be quite interesting. Being able to see the process from sheets of steel to a PK200 sitting in the parking lot was educational, to say the least. After the day concluded, we went back to the hotel, and the operators enjoyed a nice dinner together thanks to PALFINGER.

Day 3 Training Center and Q/A

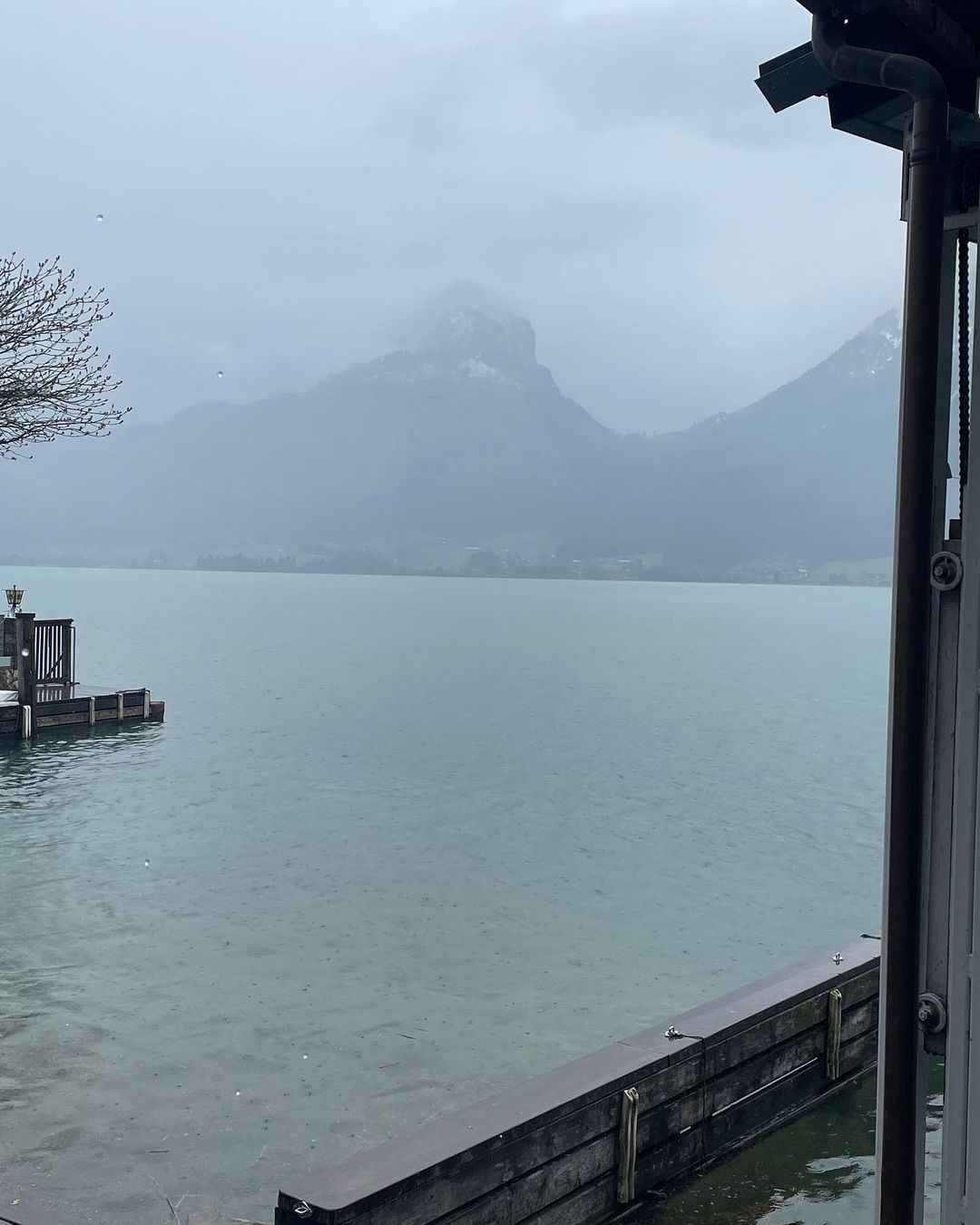

Day 3, we traveled to the training center in Salzburg. We were greeted by the heads of the International Training Team. We learned about the new TEC crane line. We were able to work as a team to calculate a lifting solution using two different cranes. We learned about the new Paldesk Features and the Apps the end-user has access to. We were given a presentation on the advances coming with the new technology and given the opportunity to ask technical questions. I found this most beneficial as I was able to gain so much insight into the operation and maintenance of my unit. I would have loved a few more hours of this. There is just so much to learn. After the classroom portion, we were about to go outside and operated three different cranes with new technologies. We all were able to test our skills with different remotes, tech cranes, smart control, and lifting challenges. At the end of the training, we worked as a team, using all three cranes to moved a known weight from spot A to spot B. It was interesting to me to watch how other operators approach the challenge and how they operate the cranes. After our morning at PALFINGER, we were treated to an awesome Mountains and Lakes tour. Despite the weather being a challenge, we toured the mountains and villages of the Austrian countryside seeing places where “The Sound of Music” was filmed and where Austrians vacation. The beauty of the landscape and the interesting architecture of the villages made for an enjoyable afternoon. After our tour, we stopped by the Red Bull Hanger 7 for a quick tour and headed back to the hotel for the evening.

Day 4

Day 4 was a trip to the Epsilon factory, where we learned about the timber recycling line and toured the factory where they assemble those booms. We were able to see how each component comes in for assembly, and the units run through various assembly stations and then to testing. We saw again some inventions PALFINGER came up with to make the assembly process more efficient and ergonomic. We had seen those on the previous factory tour as well. It’s quite amazing. They make a base that [is] articulated to mount the cranes on for assembly and testing. All designed and made in-house. From the complete tour of Epsilon to a traditional Austrian lunch, we then had the afternoon on our own to explore. I walked around the city, shopped, toured various sites, climbed to the castle, saw the gardens, enjoyed a coffee, and made the absolute most of the time we had. I truly enjoyed this fantastic city and could say so much more about the trip. At the end of the day, we all met again at a historic Brew House for dinner with the PALFINGER team. This was our last dinner together so we spent less time talking shop and relaxed a little bit more. The food was great, and the beer was even better than I had anticipated. At the end of the night, when they finally kicked us out, everyone headed back to the hotel. Unfortunately, I would be leaving early the next morning and would miss lunch at the world HQ, so I said my thanks and goodbyes.

Day 5

The next morning I began my 20-hour journey home feeling satisfied, educated, and thankful. I am truly grateful to PALFINGER for this opportunity and humbled by all the friends who voted for me. What a great honor it was to be selected to participate in the Reach Anything Challenge events.

Tell us about yourself and your company.

I currently live in a small town, Pottsboro, Texas, but grew up in an even smaller town named Caliente, Nevada. I am married to the love of my life, Mallory Smith, for (almost) 10 years. We have three kids together, Gabriel (9), Noah (7), and Ember (3).

How many years have you been in business?

When I first moved to Texas, I bounced around between a couple different jobs but found a home at Foxworth. After delivering lumber and roof trusses for nine months, they came to me about operating one of our material handling cranes since I had a little prior experience operating machinery in previous jobs. From then on out, I have been able to grow my operating skills and learn from many different people.

What does an average day on the job look like?

We start out pretty early in the morning (especially during the Texas summer heat) once we get to a house or job site, we scan the house for different ways to scatter drywall throughout the house. Once we determine the best route, I set up my truck. And get all our tools ready, and start to load the house with drywall.

Normally, we stock around 5 to 6 houses a day.

What challenges do you face?

Some of the houses we go to, are very far off the road or have obstacles like trees, power lines etc. Which can make it complicated to get our job done.

Tell us about your experience with your material-handling crane.

PALFINGER has definitely made moving around those obstacles easier, and safer. Knowing that the crane is built to reach its full capacity in any way I need it to, has made it to where I don’t have to worry whether I can get the job done or not.

What is your favorite part of your material-handling crane?

The truck stability (HPSC). A lot of times, I am not able to have my stabilizers fully deployed but just knowing that the stability will always be there, makes it that I don’t have to worry about so many different things during a job.

What is your favorite thing about PALFINGER?

Having the support of a PALFINGER specialist (Jose De Leon) that has been in this industry for many years. He has been able to adapt each truck for our needs, [which] in turn has made our jobs much easier. When it came time to design our truck, he listened to our needs and designed it based on his extensive knowledge of our market as well.

What is your favorite thing about your trip to Austria?

If I had to choose one thing that stuck out the most to me, it would be the organization of each and every step of the process to make, assemble, and test each product. With so many parts, and steps, it could easily be a giant mess, and things could get confusing and even dangerous, but it wasn’t.

Day 1

Was a day to unwind and relax, got to explore Salzburg at our leisure. We all met up to walk to dinner at Imlauer Sky Restaurant, with such an incredible view almost as good as the dinner.

Day 2

We toured the new remodeled PALFINGER World, seeing all the different equipment PALFINGER offers. And getting to play in their “men['s] playground” with all their remote control mini trucks. After lunch, we got a personal tour of the factory, which was fascinating in itself. One of the most fascinating things I observed was how clean and organized everything was.

Day 3

We were taken to the Training Center and got an insight on new technology that is being developed. Then we got to operate and experiment with some of the new features on real equipment. When it was time for lunch, you could definitely feel each operator's sadness that we had to put away our “toys”. After lunch, we were taken on a scenic tour around Salzburg and its surrounding areas. It was very relaxing.

Day 4

We were taken to their Epsilon factory, where they make their timber and recycling cranes. Once again, surprisingly clean and organized as well. The view outside was so relaxing and made us all think that it would be impossible to have a “bad day” at work with a view as beautiful as that. We then had some free time after lunch. A small group of us went on a cable car ride up Mount Untersberg. Once up top, it was absolutely breathtaking. It was very hard to come back down.

We once again had some more free time to explore Salzburg and relax until dinner time, where we enjoyed the company of many PALFINGER experts and sharing ideas and stories. We were all having such a great time exchanging stories, and the owner of the restaurant kindly asked us to leave because he was ready to go home!! Time had escaped us because we knew the trip was coming to an end, and we didn’t want it to!

Day 5

Friday morning came, and it was time to pack up all our stuff and memories. We were treated to a fantastic lunch at PALFINGER's headquarters. But before lunch, Mr. Hannes Palfinger greeted us, and took a couple minutes to get to know us, and asked us how we [had] enjoyed the trip so far. As each of us shared our goodbyes, it was almost as difficult as saying “bye” to your own family member. We had all created such a close bond in a short amount of time, and it was definitely difficult to say goodbye.

Overall I had an extremely good time; I would not trade this experience for anything. The hospitality and friendliness of everyone involved with PALFINGER was beyond imagination.

Just like Steve and Neal, we have the right options to fit your needs. Check out our full line of knuckle boom cranes and material handling cranes that can handle the unique needs of your industry.

Some photos courtesy of Steve Connally and Neal Smith.

Explore More

Contact Us

View All Knuckle Boom Crane Models

View All Material Handling Models

JohannesRadlwimmer.jpg)

JohannesRadlwimmer.jpg)

JohannesRadlwimmer.jpg)

JohannesRadlwimmer.jpg)

JohannesRadlwimmer.jpg)

.jpg)