Service

COMMANDE DE PIÈCES DÉTACHÉES

Commandez tout simplement vos pièces de rechange dans notre boutique en ligne. Avec le numéro de série de l’appareil, vous allez trouver exactement les pièces détachées nécessaires pour votre hayon élévateur*. Vous avez ainsi la possibilité de passer votre commande 24/24.

Cliquez ici pour accéder à la boutique en ligne pour hayons élévateurs PALFINGER

Vous pouvez bien entendu également contacter directement nos techniciens compétents au numéro suivant :

Tél. : + 33 0810 000 374

Du lundi au vendredi de 8 h 30 à 12 h 30 et de 14 h à 17 h 30

Une commande par fax peut être envoyée facilement avec notre formulaire.

*Utilisable pour les hayons élévateurs PALFINGER à partir du numéro de série commençant par 8xxxxxx.

FORMULAIRE D'INSRIPTION

Following the delivery of a tail lift, customers require comprehensive service support for many years to come. In order to meet these demands the best way and to serve as your dependable partner whenever you may need us, we have introduced an extensive online resource tool for your convenience. Our online customer service resource tool offers you comprehensive service, information and order forms.

Feel free to use the following options:

- Order spare parts online

- Get answers to frequently asked questions

- Submit warranty claims

- Select training dates

Do you prefer a personal contact? Then give our service hotline a call: +49 4221 853 355.

MOUNTING STUDIES

Before placing an order, it is important to properly assess the technical data for mounting on the vehicle. We have a team that deals exclusively with different assembly situations to decide how the tail lift has to be installed on the vehicle and which tasks have to be considered when special equipment is used.

You can get a personal mounting proposal for your project, if you fill in the document given below completely and send it back to us (Fax no. +49 4221 853-345).

DÉPANNAGE

Do you need technical support or documentation? Please contact us by phone (+49 4221 853 355)

Wiring diagrams are also available in our online portal.

IMPORTANT INFORMATION:

Every tail lift from PALFINGER Tail Lifts is supplied with a specific electrical and hydraulic diagram for the respective tail lift type. These documents are located directly next to the circuit board in the main tube.

You will find direct help on the following points here:

- Identification and classification of the tail lifts

- Electrical and control system

- Hydraulics

- Cylinder setup and repair

- Emergency functions

- General maintenance and service tips

IDENTIFICATION AND CLASSIFICATION OF THE TAIL LIFT TYPE

Tail lifts differ in a few, but decisive features. It is therefore important to know the exact type of your tail lift in order to, for example

- Order the right spare parts

- or to determine the correct electrical and hydraulic plan

THE MOST IMPORTANT DIFFERENTIATING FEATURES INCLUDE

- the load capacity (e.g. 1000 kg for a standard load distance)

- the tail lift model (e.g. Cantilever / Foldable / Retractable / Vertical)

- the year of manufacturing (relevant for technical developments and model adaptations).

This information can be found on the type plate of your MBB tail lift. The type plate is usually attached in two places:

- on the rear of the platform

- on the mounting tube / main beam – attached either on the top of the driver’s side or on the underrun protection

In addition, there should always be an inspection logbook in the vehicle documents. This is required for routine inspection according to the European machine norms and will be checked by a certified expert.

ELECTRIC AND CONTROL SYSTEM

The control systems of our tail lifts have been continuously developed over the last few years. The focus has been on ergonomic aspects as well as economic and technical requirements. The MBB Control system is a real benchmark in this area - it can be used in all PALFINGER Tail Lifts across all series, setting the benchmark in terms of ease of use, efficiency and reliability.

CURRENT PALFINGER TAIL LIFTS CONTROL SYSTEM TYPES

• MBB Control Eco, Plus or Premium

• Basic E

Hydraulics

The hydraulics in our tail lifts are reliable and based on a system that has been tried and tested over many years. A quick glance at the hydraulic diagram of the respective type makes it easy to understand how it works. Our standard hydraulic diagrams can be found in the operating instructions. In addition, each tail lift comes with an individual electrical and hydraulic diagram - this is located directly next to the control board in the main beam.

CYLINDER SETUP AND REPAIR

The cylinders of all our tail lifts are made by us exclusively in-house. This enables us not only to offer you all components as spare parts, but also to guarantee the proven PALFINGER quality that has been in place for decades and to continuously develop it further.

In the following section, we will show you how to replace the seal kit of the tilting cylinders. The repair can be carried out directly on the vehicle; it is not necessary to remove the entire cylinder. It takes about an hour and can be carried out by a single person: Guide to replacing a seal kit

EMERGENCY FUNCTIONS

In the event of a malfunction on the road, the top priority is to get the vehicle out of the danger zone. The controls of the tail lifts from PALFINGER Tail Lifts make it possible to deactivate unnecessary consumers in order to eliminate possible sources of interference. This enables systematic troubleshooting - the tail lift can be put into transport position and the vehicle can be transferred to a service or partner company as quickly as possible.

ACTIVATING EMERGENCY MODE

For the K, K-Plus, K-1 Plus, MBB Control and Basic E series

In the event of a defective sensor, the tail lift can be moved via emergency operation - sensors are no longer queried.

Operation via one- or two-hand control:

- Press the “Open”, ‘Lower’ and - if available - the “Additional switch” buttons simultaneously

- Hold these down for at least 10 seconds

Operation via Slimpanel:

- Press the additional button and any three function buttons simultaneously

- Press and hold for at least 10 seconds

- “E” appears in the 7-segment display - the tail lift is now in emergency mode

- Automatic processes are deactivated

IMPORTANT NOTE ON EMERGENCY OPERATION: Risk of material damage in emergency operation!

All sensors are deactivated in emergency mode. The tail lift can move beyond the set limit positions - this poses a risk of material damage!

- Observe all movements carefully

- Release the operating elements when the tail lift reaches an intended position.

CLOSING THE PLATFORM IF ALL CONTROL PANELS FAIL

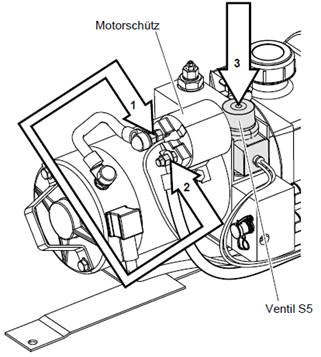

If the tail lift cannot be controlled via the operating elements even in emergency mode, it is possible to close the platform manually. To do this, actuate the motor contactor and valve S5 directly on the hydraulic unit - this allows the platform to be moved in safely and the vehicle to be made ready for use again.

Access to the hydraulic unit

For tail lifts with slide-in unit

- Open the right-hand cover of the stand tube

- Loosen the fixing bolt of the hydraulic unit on the stand tube.

- Pull out the hydraulic unit until the motor contactor and valve S5 are accessible.

For tail lifts with box-type, universal or reversible unit

- Loosen and remove the unit cover.

Lifting the platform

- Bypass contacts 1 and 2 on the motor contactor until the platform has reached the loading height.

Closing the platform

- Bypass contacts 1 and 2 on the motor contactor.

- Actuate valve S5 at the same time by pressing it in, e.g. using a screwdriver.

Completion of the process

For tail lifts with slide-in unit

- Slide the hydraulic unit back into the stand tube and fix it with the fixing screw.

- Close the right cover of the stand tube.

For tail lifts with box-type, universal or reversible unit

- Put the unit cover back on and secure it.

GENERAL SERVICE ADVISOR

Regular maintenance is essential to ensure that your tail lift works reliably over the long term. It starts with simple measures such as lubricating the bearings and checking the cap bolts and extends to checking the hydraulic hoses and hydraulic oil, as well as checking the electrical components. On this page, we have compiled useful tips and recommended measures that you should observe during the daily use and maintenance of your tail lift.

SERVICE AND MAINTENANCE

In general, your tail lift should be maintained as required and regularly subjected to a professional service.

| TASKS | DAILY | DDEPENDING ON USE | MONTHLY |

ANNUALY |

|

Checking the effectiveness and presence of the safety and warning devices |

x |

|||

|

Cleaning the tail lift |

|

x | ||

|

Checking the battery |

|

x | ||

|

Checking the carbon brushes on the electric monitor |

|

x | ||

|

Check the oil level and top up if necessary |

|

x | ||

|

Checking the bolts and nuts for tightness |

|

x | ||

|

Lubricating the low-maintenance bearings |

|

x | ||

|

Changing the oil |

|

x |

IMPORTANT PRACTICAL TIPS:

- Grease bearings regularly: All bearing points should be greased according to the intensity of use to avoid unnecessary wear.

- Oil change recommended annually: The hydraulic oil should be changed annually, e.g. before winter.

- Check carbon brushes: Carbon brushes are wearing parts. Depending on the frequency of use (single or multi-shift operation), an inspection is recommended 1 to 4 times a year (damage due to worn carbon brushes is not covered by the warranty)

You will find the complete maintenance and service schedule in your inspection booklet.

Lubricants and operating fluids

Hydraulic oil – Recommendations

Standard version:

Shell Tellus S2 V 15

Operating temperature: –20 °C bis 60 °C

Special configuration „cold“:

Aero Shell Fluid 41

Operating temperature: –54 °C bis 90 °C

Lubricating grease/oil – Recommendations

For bearings on the tilt and lifting cylinders

• Shell Gadus S2 (heavy-duty grease)

• Comparable grease

For movement rails on retractable tail lifts:

• Interflon Grease OG

• Comparable grease

For plastic bearings:

• Interflon LUBE EP+

• Comparable lubricating oil

DEMANDE EN GARANTIE

Pour un suivi rapide et facile de votre demande de garantie, notre service de réclamation électronique est maintenant disponible surwww.eetk.eu.

Suivez simplement le lien e-claim dans le menu.

Si vous avez d'autres questions, n'hésitez pas à contacter notre service client.

FORMATIONS

OBJECTIF ET CONTENU DES SESSIONS DE FORMATION PALFINGER

Notre monde en changement perpétuel entraine des changements rapides de l'équipement technique et des installations, et ce à un rythme plus élevé qu'auparavant. Des améliorations sont continuellement intégrées dans nos systèmes techniques pour répondre à la disponibilité de composants de base et d’appareils électroniques plus puissants. Un nouveau matériel remplace l'ancien et des technologies de production modernes permettent de travailler avec une plus grande précision et donc d'offrir une meilleure qualité.

C'est évidemment aussi le cas pour nos hayons élévateurs. Le meilleur exemple de ce changement est notre système de contrôle électronique innovant, qui n'est pas seulement plus efficace que l'ancien modèle, mais qui offre également plus de fonctionnalités. Cela signifie bien entendu que les spécialistes de nos centres de maintenance doivent s'adapter et maitriser les modifications intégrées à nos hayons élévateurs toujours plus vite. C'est pourquoi PALFINGER organise - directement sur place - des sessions de formation professionnelles exhaustives pour que tout le monde soit toujours parfaitement qualifié !

Nos experts utilisent des maquettes, schémas de câblage, fiches techniques et programme de diagnostique pour expliquer comment l'équipement est construit et comment identifier plus efficacement l'origine d'un problème grâce au matériel de formation exhaustif.

À la fin de la formation, PALFINGER décerne à chaque participant un certificat prouvant qu'il ou elle a suivi la formation avec succès. Le participant est alors considéré comme un expert technique et est autorisé a effectuer des inspections régulières des hayons élévateurs. La formation est conçue pour le personnel spécialisé qualifié chargé d'effectuer des travaux de maintenance et de réparation sur les véhicules et leurs accessoires.

Le personnel qui participe aux formations doivent être familiarisés avec les schémas de câblage et/ou les systèmes hydrauliques et sont chargés de travaux de réparation sur des véhicules ou des installations électriques et hydrauliques. Les formateurs se concentrent donc sur les aspects électroniques et hydrauliques des hayons élévateurs. La formation est accompagnée de matériel de démonstration, tel que des élévateurs et des cylindres de fermeture, des blocs d'alimentation avec moteur et pompe ainsi que des soupapes, panneaux de contrôle, pupitres de commande et connecteurs.

TÉLÉCHARGEMENTS

La vue d'ensemble suivante contient les certificats actuellement disponibles en fonction de la date de publication CEE-ONU règlement no 58 pour les dispositifs arrière de protection antiencastrement – série 02 et “nouveau” 03 d’amendements:

Cantilever

C 750 L

C 750 LX

PTC 750 L/LLW

C 750 S (1)

C 750 S (3)

C 750 S (3)

C 750 SLW

C 750 SPL/SPR

PTC 750 S

PTC 1000 LLW

C 750 LD – C 1500 ML

C 1000 SPL/SPR 1/3

C 1000 SPL/SPR 2/3

PTC 1000 L – PTC 1500 L

PTC 1500 S – PTC 2500 L

C 1000 S – C 3000 S

C 1500 SZ – C 2000 LZ

C 2000 SK – C 2500 SK

Foldable

F 1000 L

F 1000 SH – F 2000 LH

F 1000 SX – F 1500 L/LX

RETRACTABLE

R 1000 LM – R 2500 S

Vertical

V 1000 LQ

V 4000