- Home

- Products

- Loader Cranes

- Highlights

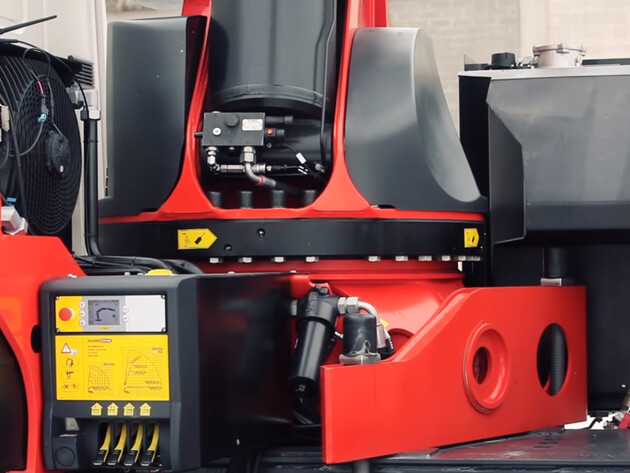

Continuous Slewing System

Unrestricted Movement

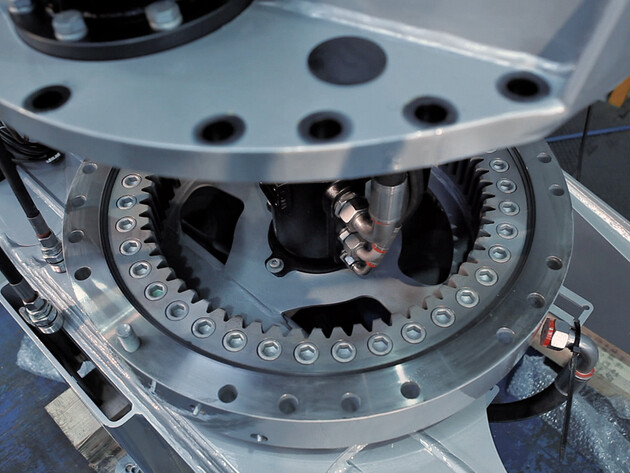

How it works

A hydraulic motor drives a pinion which meshes with a basemounted high quality roller ball bearing, rotating the crane. The gears are precision machined to minimize back lash between the gears. The roller ball bearing is made with very tight tolerances for width, flatness, and perpendicularity. The matching surfaces on the base and the column are machined in a single clamping for the highest possible accuracy. On larger cranes two identically sized slewing motors are set across from each other on the column. One motor is hydraulically preloaded against the other, which eliminates all backlashes in the rotation system.

Benefits

More Efficiency in Use

- Faster cycle times because the crane can be slewed over a shorter distance. The crane works more efficiently and faster

- Higher slewing moment through minimized friction in the slewing mechanism

A great Variety of Applications

- Crane can be used independent of the vehicle position

- Load handling also possible in tight spatial conditions

Safe Crane Operation

- Safe and smoother operation due to elimination of catching endstop

- Accurate positioning of loads due to low clearance on slewing mechanism

Maintenance and Service-Friendliness

- Very little maintenance is needed on the ball bearing slewing ring

Increased Resale Value

- Longer service life of the slewing system because of the ball bearing slewing ring