- Home

- News

Smart Operations Planning with the PALFINGER Job Planner

From paper and pencil to digital scheduling: With its Job Planner, PALFINGER simplifies the planning of loader crane operations for fleet managers and operators, thereby increasing efficiency and safety.

An example: moving a 400-kilogram whirlpool into the garden over a garage. The challenges arise on site. A narrow street requires adherence to distances and safety measures. In addition, the curbs and the load-bearing capacity of manhole covers must be taken into account. On the roof of the main building, there is a new PV system that must not be damaged. For the crane operator, planning work awaits.

Until now, this was done with printed load charts, graph paper, and pencil. “Manual calculations cost valuable time and present a high potential for error. A small miscalculation can have massive consequences,” explains Stefan Kreuzer, Product Manager for CONNECTED. But there is a digital solution for both pre-planning and ad-hoc planning of lifting operations: the PALFINGER Job Planner – part of CONNECTED plus+. With new features available from this year’s bauma, it optimizes the entire planning process and increases the safety and efficiency of crane operations.

Precise Planning for Maximum Safety

Accurate planning is crucial for a safe and efficient lifting operation. Faulty calculations can lead to unstable positions or misjudgments of the lifting capacity. Unlike telescopic cranes, knuckle boom cranes enable complex load movements in tight or hard-to-reach areas. However, their high flexibility requires precise planning that takes into account load limits, geometry, stability, and local conditions. “The versatility of a knuckle boom crane is impressive, but it does impose high demands on planning. Every movement must be carefully thought out,” says Stefan Kreuzer.

Unforeseen Challenges in the Whirlpool Installation

Back to the whirlpool that is to be moved into the garden. All calculations are complete, and even a potential road closure was requested in time. But then the wind blows stronger than expected, and in gusts no less. The calculations must be redone immediately. “The conditions on site often change unexpectedly— even a wrongly parked car can disrupt the entire plan. In such moments, quick decisions are required: can the lifting operation be carried out from a different position, or does the car need to be towed away?” describes Stefan Kreuzer.

Smart Support with the Job Planner

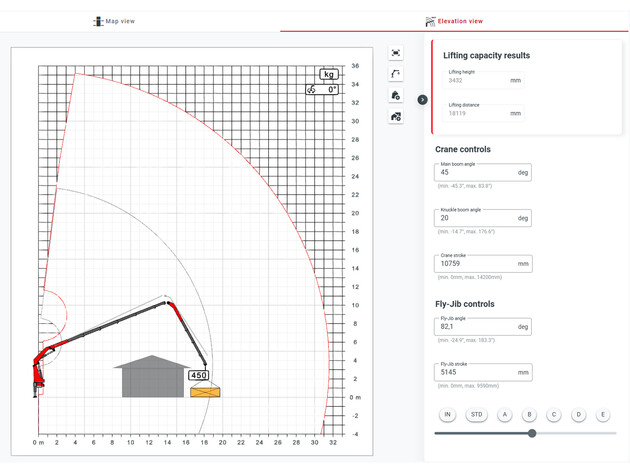

In this case, PALFINGER’s digital Job Planner sets new standards. Using all available data, the software enables both rapid and precise calculation of crane operations. It takes into account the specific crane configuration on the vehicle, the planned support situation, as well as load capacity data across the entire load curve. This simplifies even the most challenging operations with knuckle boom cranes. Particularly helpful is the planning facilitated by the combination of a bird’s-eye view – either directly in Google Maps or via a to-scale construction site plan – and the newly available side view. The side view now also allows obstacles such as buildings or other disruptive edges to be included in the planning. “The additional visual display in the side view helps to identify and resolve potential issues in advance. This saves time and minimizes risks,” explains Kreuzer.

Quick Response to Changing Conditions

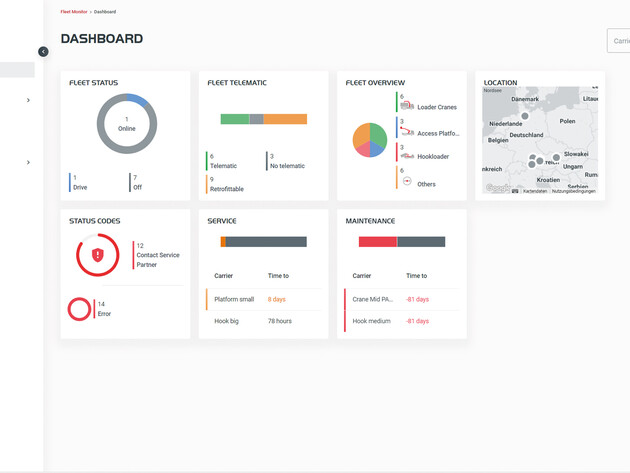

With the Job Planner, the vehicle position and crane configuration can be adjusted directly on site. “If the planned position is blocked, we have to react immediately. With the Job Planner, the operator on his smartphone checks whether an alternative position is possible or if the planned one needs to be cleared,” Stefan Kreuzer describes the advantages of flexible ad-hoc planning. Thanks to the operator version on the smartphone, or via the Fleet Monitor in the office, changes can be reviewed in real time and communicated to the operator on site.

More Efficiency and Better Communication

A decisive advantage of the Job Planner is the ability to generate a detailed planning report. This not only supports coordination with site managers and clients but also facilitates the application for official permits, such as road closures.

“This avoids misunderstandings in communication. In addition, with the latest version, elements of the planning can be exported in the form of documents – a decisive added value for legal evidence and customer documentation,” emphasizes Stefan Kreuzer.

Conclusion: An Indispensable Tool for Deployment Planners and Crane Operators

The PALFINGER Job Planner greatly simplifies the planning process by enabling faster and more accurate calculations, thereby increasing safety and improving communication. This makes digital planning an indispensable tool for dispatchers and crane operators, significantly contributing to more efficient and safer construction site operations.

INFOBOX: About the PALFINGER Job Planner and PALFINGER CONNECTED plus+

The Job Planner for loader cranes is part of PALFINGER CONNECTED plus+ and was expanded in spring 2025 to include the new capabilities of the side view with object integration as well as real-time load curve calculation. With it, operations can be planned in detail or redesigned at short notice on site. Thanks to the new side view and the ability to mark disruptive edges, it can be verified in all three dimensions whether the load can be lifted to the desired location – taking into account height restrictions and obstacles. The Job Planner is available for both dispatchers (Fleet Monitor) and operators (Operator Monitor).

An integrated data interface ensures that customers can take full advantage of PALFINGER CONNECTED plus+ regardless of the fleet management system used – thanks to the standardized AEMP 2.0 export.

ABOUT PALFINGER AG

PALFINGER is an international technology and mechanical engineering company and the world’s leading producer and provider of innovative crane and lifting solutions. With around 12,350 employees (without contract workers), 30 manufacturing sites and a worldwide, comprehensive sales and service network, PALFINGER creates added value from the challenges of its customers. PALFINGER is consistently continuing on its course as a provider of innovative, complete solutions that deliver increased efficiency and better operability, while leveraging the potential of digitalization along the entire production and value chain.

PALFINGER AG has been listed on the Vienna stock exchange since 1999, and in 2024 achieved revenue of EUR 2.36 billion.

For further information please get in contact with us: emea-marketing@palfinger.com