- Home

- News

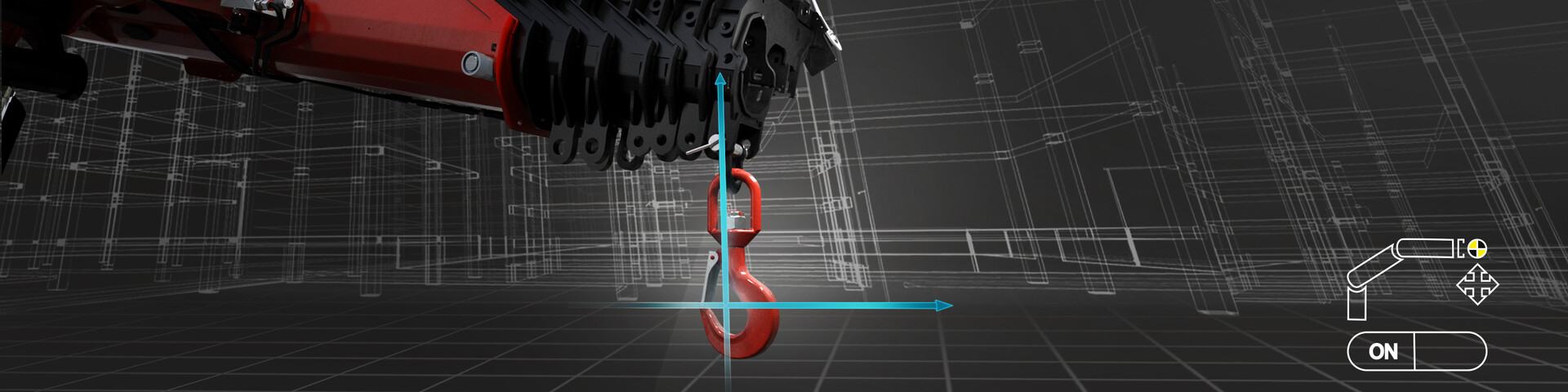

Controlling the tip of the crane more efficiently and intuitively

With its intelligent crane control, PALFINGER is once again innovation leader: Smart Control makes working with the crane even more efficient by intuitively controlling the crane tip. The intelligent system gives crane operators additional freedom for more complex lifting operations.

Recycling bins that have to be emptied in residential complexes; bulk material that is spread with grapples or foundations that are set with earth augers: These are all jobs that can be done faster and easier with the new intelligent crane control. This saves time and increases the efficiency of work operations. Thanks to this intuitive technology at Smart Control, the crane operator can focus entirely on the load and the environment, and concentrate on the more complex phases of the lifting operation itself. "We want to make working with a loader crane even easier, more efficient and smarter," says Michael Völker, Head of Product Management Loader Crane at PALFINGER. At the end of the day, the new crane control system of the crane tip results in more lifting operations and thus greater profitability.

Crane operation simply smart

The crane tip can be moved vertically or horizontally to the desired position with one lever movement on the radio remote control. With conventional control, this requires several lever movements. The logic of the movements of the new crane control is processed in the PALTRONIC control unit. In the background, the system independently calculates the direction of movement using sensors and electronics. In conjunction with the HPSC-Plus LOAD function, the truck inclination can also be included and compensated.

When the extension boom system is fully extended, Smart Control calculates the boom system deflection and automatically compensates it. Thanks to Flow Sharing, the electronic oil volume distribution system, the required hydraulic oil always adapts to the current requirements. This guarantees smooth movements of the crane. When the crane operator does not need Smart Control, he can simply deactivate or override it at any time.

Loader cranes with Smart Control can even be operated with an additional knuckle boom system. In this case, the main boom, knuckle boom and extension booms are operated via the new type of crane control; conventional control is used from the additional knuckle boom system onwards. Additional equipment such as grapples, pallet forks or earth augers can also be integrated.

Another advantage is that the new system can be learned quickly thanks to its intuitive and simple operation. The training period for new crane operators or experienced ones on new PALFINGER crane models is shortened

PALFINGER is the first loader crane manufacturer, who offers an innovative crane control system of the crane tip, like Smart Control, for the entire range from 29 to 58 meter-ton. Up to eight extensions can be controlled - covering the entire TEC 7 models from PK 29.502 TEC 7 to PK 58.002 TEC 7.

With Smart Control, operating a loader crane has become a bit easier again - in line with the motto: PALFINGER. Turns hard work into smart work!

ABOUT PALFINGER AG

PALFINGER is an international technology and mechanical engineering company and the world’s leading producer and provider of innovative crane and lifting solutions. With around 12,350 employees (without contract workers), 30 manufacturing sites and a worldwide, comprehensive sales and service network, PALFINGER creates added value from the challenges of its customers. PALFINGER is consistently continuing on its course as a provider of innovative, complete solutions that deliver increased efficiency and better operability, while leveraging the potential of digitalization along the entire production and value chain.

PALFINGER AG has been listed on the Vienna stock exchange since 1999, and in 2024 achieved revenue of EUR 2.36 billion.

For further information please get in contact with us: emea-marketing@palfinger.com