- Home

- News

Where every centimetre counts: PCC 57.002 Indoor Solution

modernising a production facility in the tightest of spaces

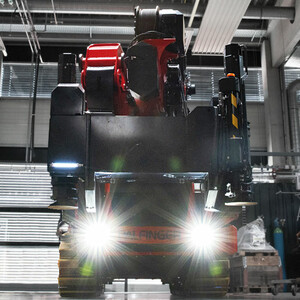

The path through the production hall of a foundry is narrow and winding. What would normally be beyond the capabilities of a regular, truck-mounted crane are the perfect conditions for the PALFINGER crawler crane PCC 57.002. It performs outstandingly well where other cranes fail. This includes not only tough off-road applications, but also – as in this case – tricky indoor conditions, which can be overcome only thanks to a versatile, manoeuvrable and adaptable crane solution.

The personnel tasked with performing renovation work in the production hall of a foundry were initially faced with a major challenge. The confined space made it difficult not only for trucks to access, but also to dismantle heavy machine parts and remove entire walls in the highly angular production hall while foundry operations were ongoing. The tight conditions made the process of installing the new conveyor systems seem like an insurmountable challenge – at least until the discovery of Maschinentransporte Eitzlmayr, whose specialists tackle challenges just like this every day. Managing Director Mario Eitzlmayer saw that this job would be perfect for the PCC 57.002, which demonstrated its impressive strengths in these challenging conditions.

Smart design for maximum flexibility

The combination of a slim design, sophisticated kinematics and high-precision control also allows heavy loads to be lifted in the narrowest and lowest passageways. Thanks to the PCC 57.002’s double linkage system, heavy loads can be lifted – including around projecting edges – even with its long-reach knuckle boom system (optionally with fly jib) and in awkward positions.

Working in the tightest of spaces

To allow it to travel along extremely low passageways, the crane can also be decoupled from its crawler chassis and moved only using the stabiliser outriggers. This shifting is also useful when the crane needs to move over obstacles or sensitive surfaces need to be protected. Managing director Mario Eitzlmayr was delighted with the outcome. ‘We saw the crawler crane for the first time at the bauma trade fair in Munich and were instantly captivated. Its compact design, high degree of manoeuvrability and flexible stabilisation options are a big advantage for us – and, of course, shifting in narrow halls in particular. Here, every centimetre really does count. For applications like these, the crawler crane is simply unbeatable!’

Flexible control thanks to PALFINGER PALcom P7

PALFINGER’s own radio remote control allows the crawler crane to be manoeuvred through any narrow passageway and past any obstacle with a high degree of precision and sensitivity. The PALCOM P7 also allows the entire crane unit to be levelled out using the easy-to-operate telescopic stabilisers, which maintain the stability of the entire system at all times. The H-shaped stabilisation frame ensures optimum stabiliser positioning and lifting power.

Conclusion

Without the PALFINGER crawler crane, more extensive modifications would have been necessary in the production hall before the actual work could even begin. But thanks to the crawler crane, modernisation work was performed extremely quickly, economically and with high precision.