In the Network of Opportunities

Strong and yet flexible at the same time — that is what distinguishes good networks. Especially when they are strategically built, and everyone is on an equal footing. Used correctly, they make companies more resilient and more innovative. PALFINGER goes one step further and integrates a wide variety of partners into a well-thought-out ecosystem.

“A strong network reduces risks. For everyone,” says PALFINGER CFO Felix Strohbichler. In a connected world, that should be self-evident. Reality, however, shows that this is not always the case. Constant volatile conditions become an ongoing stress test for networks of relationships. Trust in a partner’s reliability and strength, along with mutual respect, plays a special role in this. “It is also important to convey this by having a strong brand and purpose-specific communication — especially in challenging times,” says Armin Schlamp, Vice President Corporate Marketing & Communications at PALFINGER.

The Supply Chain Network

“It doesn't always have to be a ship in the Suez Canal. Or a global pandemic,” says Simon Davis, who is driving supply chain transformation for PALFINGER. The causes that block supply chains and shut down production are manifold. Above all they are constantly increasing. The supply chain management team at PALFINGER counters volatile conditions and is responsible for building a resilient value chain. The team has been driving forward strategic supply chain management for almost three years focusing on supply chain transformation as a first step.

GPO as the basis

Supply chain management is based on the Global PALFINGER Organization (GPO). The globally oriented matrix structure combines efficiency, flexibility and market focus to promote international cooperation using uniform processes and standards. Local teams react flexibly to customer needs, using global expertise and resources. This network enables rapid reactions to market changes, drives innovations and creates solutions that can be applied all over the globe.

Customer-focused, resilient and adaptable

Gerhard Innerlohninger, Head of Global Supply Chain Planning & Performance, describes the optimum basis for a mature supply chain: “Above all, it must be customer-driven – it focuses on what our customers and the market need. It must also be robust and adaptive, in other words, flexible. With everything we do this is what we want to achieve.” 16 initiatives, which are staggered into different phases, create sustainable changes at organizational, process and system levels. They include tasks and activities that take place across all areas of the company – from purchasing and sales to production, and from logistics to financial management. “This transformation is the key to remaining successful over the long term,” explains Transformation Program Manager Simon Davis.

A strong, international network of strategic partners

This transformation is also reflected in a change in strategy: Instead of buying in services, they are developed together with partners. These supply alliances, or strategic partnerships, go far beyond traditional supplier relationships. It is about developing together, about growing together – in a shared ecosystem.

With this approach, PALFINGER is increasingly working together with larger, globally active partners. “In the future, we will establish more international partnerships – with companies that, together with us, operate across at least two continents,” says Mühlbacher.

The Development Networks

The counterpart to the supplier network is the field of research and development. This ecosystem – which includes the Technical Universities of Vienna and Graz, the Austrian Institute of Technology (AIT), the Fraunhofer Institute and the University of Applied Sciences Upper Austria – is working on innovations in the fields of autonomy, connectivity and eco-efficiency.

“According to the front-runner principle, one of our product lines always takes on the leading role. It is supported by central development resources and supplemented by the know-how of external partners,” says Sebastian Wimmer, head of the ACES program at PALFINGER, which focuses on precisely these autonomous, connected and eco-efficient solutions. Together with partners such as AIT, technologies are being developed that revolutionize lifting processes and become the foundation for applications in many PALFINGER divisions.

Autonomous solutions of the future

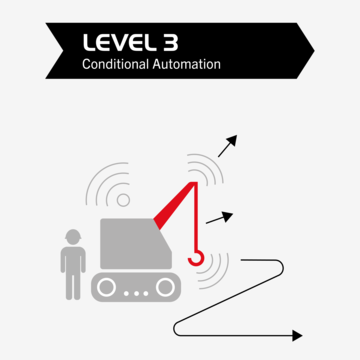

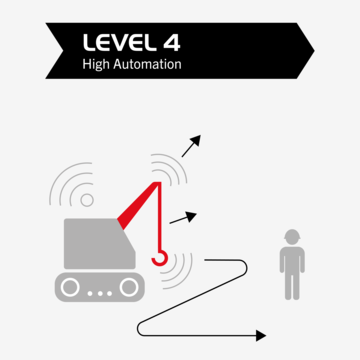

Building new solutions always starts with complex issues. For example, how timber cranes accurately detect tree trunks, how their position can be precisely determined and how they should be gripped and removed efficiently. PALFINGER Epsilon and the company's own Köstendorf Technology Center are working on finding answers to these issues together with AIT. The “Go Autonomous” project goes beyond environment recognition and automatic loading. Reaching autonomy level 4 could enable the operator to work on other tasks simultaneously.

Precisely detecting logs, accurately determining their position, and efficiently gripping and placing them – PALFINGER EPSILON and the Austrian Institute of Technology are working together to develop an autonomous solution for timber cranes.

It is not only research partners who are involved in project development. The focus is always on the challenges faced by customers. Whether it's small businesses in Austria or large associations of forest owners in Sweden – all suffer from the severe shortage of well-trained crane operators for timber harvesting. Accordingly, interest in autonomous systems is enormous.

AIT researcher Manfred Gruber underlines the long-term impact of cooperation between industry and science: “It boosts the competitiveness of industry partners and adds to the fields of application for the technologies developed at AIT. This promotes technology transfer and the practical implementation of innovative solutions to the benefit of the industrial location.”

Connecting common challenges

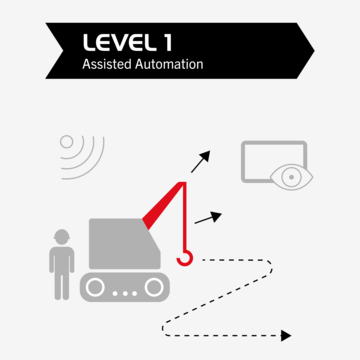

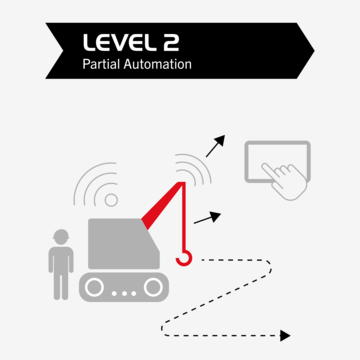

Common challenges provide an excellent basis for a valuable network. For example, PALFINGER has teamed up with Ammann, Prinoth, Rosenbauer and TTControl in the Autonomous Operation Cluster (AOC). Together, the companies are developing key technologies for the assisted and autonomous operation of machines and off-highway vehicles. Whether it's a construction machine, crane, fire department equipment or snow groomer — assistance functions that take pressure off operators while simultaneously increasing productivity, efficiency and safety are central considerations for all partners.

Remote operations at Sea

When a project transitions into series production, PALFINGER works closely with established industry and production partners. One example is the long-term cooperation in offshore cranes with the Norwegian oil and gas company Aker BP and Optilift, a company specializing in digital solutions for on- and offshore cargo handling.

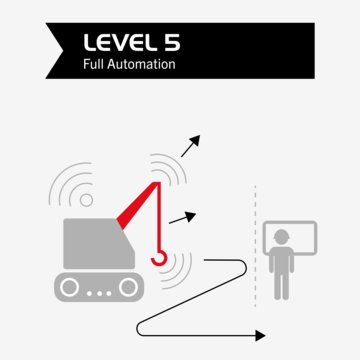

“We have an ambitious remote operating strategy, where cranes are an essential enabler,” says Julie Jansen Birkeland, who is a project manager for performance-based contracts at Aker BP. For a good reason. At sea, cranes face unique challenges: extreme weather conditions, high waves, limited visibility, and the complex handling of heavy loads require the utmost precision. Autonomous solutions are revolutionizing this sector by using sensor technologies and artificial intelligence to take over critical tasks. They automatically compensate for wind and wave influences, detect potential hazards well in advance, and operate with consistent efficiency. This relieves operators, enhances safety, and ensures reliable, precise operation even under extreme conditions.

Together with its partners, PALFINGER is developing new remotely operated offshore cranes. A total of seven cranes will be delivered to Aker BP, five of which can be fully controlled from a remote operations center onshore in Stavanger, Norway.

“In our collaboration model, key technical resources from all partners are involved at an early stage. This lays the foundation for a robust all-electric standardized design and technical development for remote operation,” says Birkeland. She highlights the economic significance of this long-term partnership: “Deep mutual understanding and shared expertise lead to a product with superior performance and, in the long run, lower operational costs.”

Camilla B. Nylund, Managing Director at Optilift, also sees real value in collaborative partnerships: “A collective approach creates solutions that are greater than the sum of their parts. In today’s fast-changing world, this is essential: being involved in the full lifecycle – from joint development to end-product deployment – provides invaluable insights, ensuring our solutions deliver unmatched value.”

And what does this mean for the future?

“The entire area of human-machine interaction plays a central role in our R&D activities,” explains Sebastian Wimmer. “Our cooperation with Aker BP and Optilift is one example of this. We are intensively exploring questions such as how the control of our cranes will look in the future, which systems can support or even partially replace the operator.”

In addition to developing smart technologies, PALFINGER is focusing increasingly on strategic planning. “I can predict quite accurately what I will sell in three months,” says supply chain planner Gerhard Innerlohninger. “But how will the market develop in the long term? Where are new growth markets emerging? Where do I need to adjust production capacities or expand my network?”

To find answers to such questions, PALFINGER is currently working on an AI-based forecasting model. This heuristic system draws on a large amount of information and data to better forecast, coordinate and plan future projects, customer requirements and necessary sales and partner networks — with unprecedented precision. Another step toward making PALFINGER's networks ever smarter and more resilient. For the benefit of all parties involved.

Into the future with AI

Into the future with AI  A changing world

A changing world  Courage to keep reinventing

Courage to keep reinventing