Railway Cranes

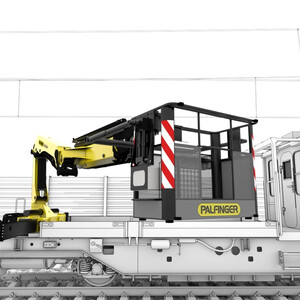

PK 23002 RW Basic Line

- Go back

- Home

- Products

- Railway Systems

- Models

- PK 23002 RW Basic Line

PK 23002 RW Basic Line

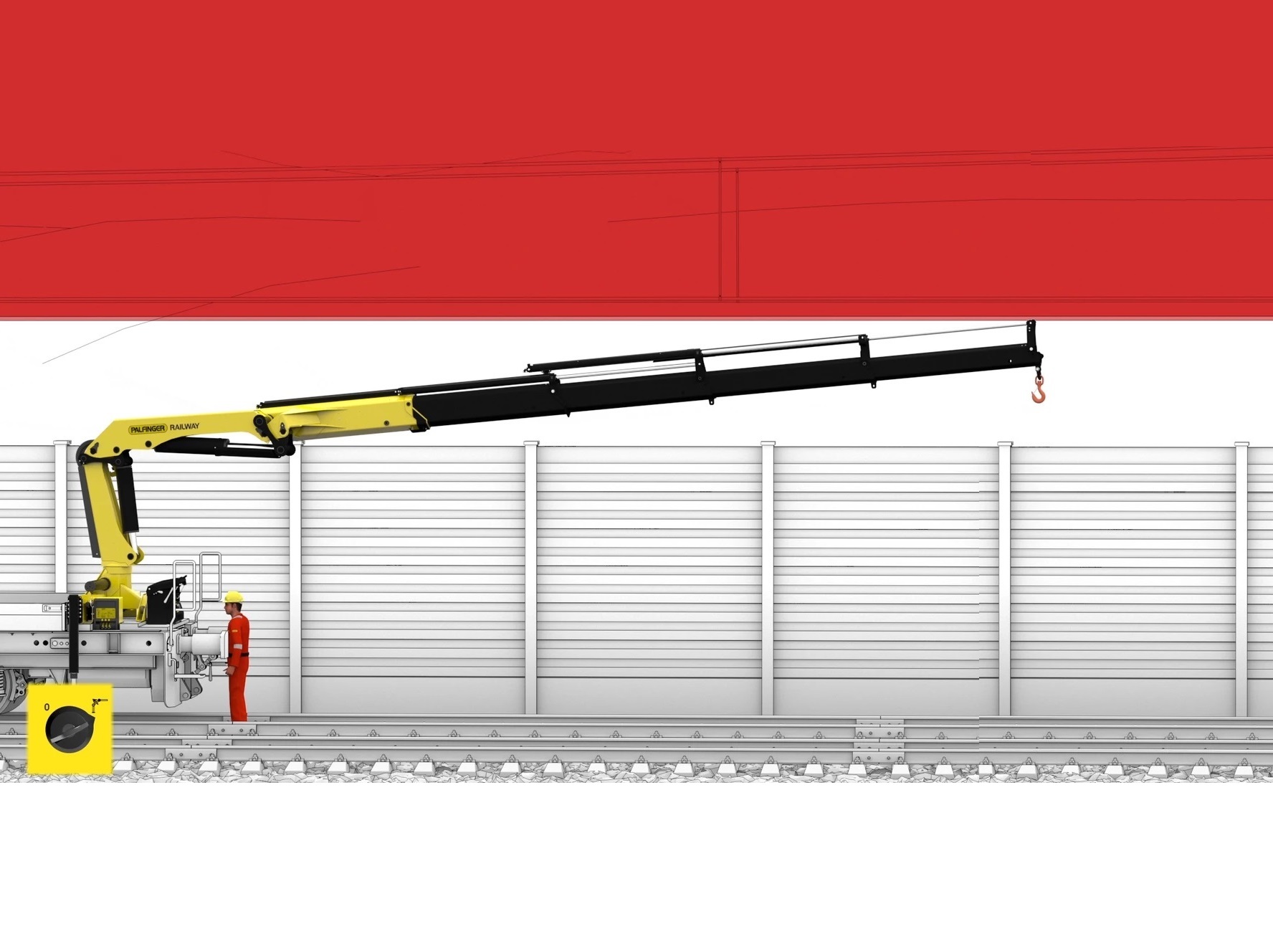

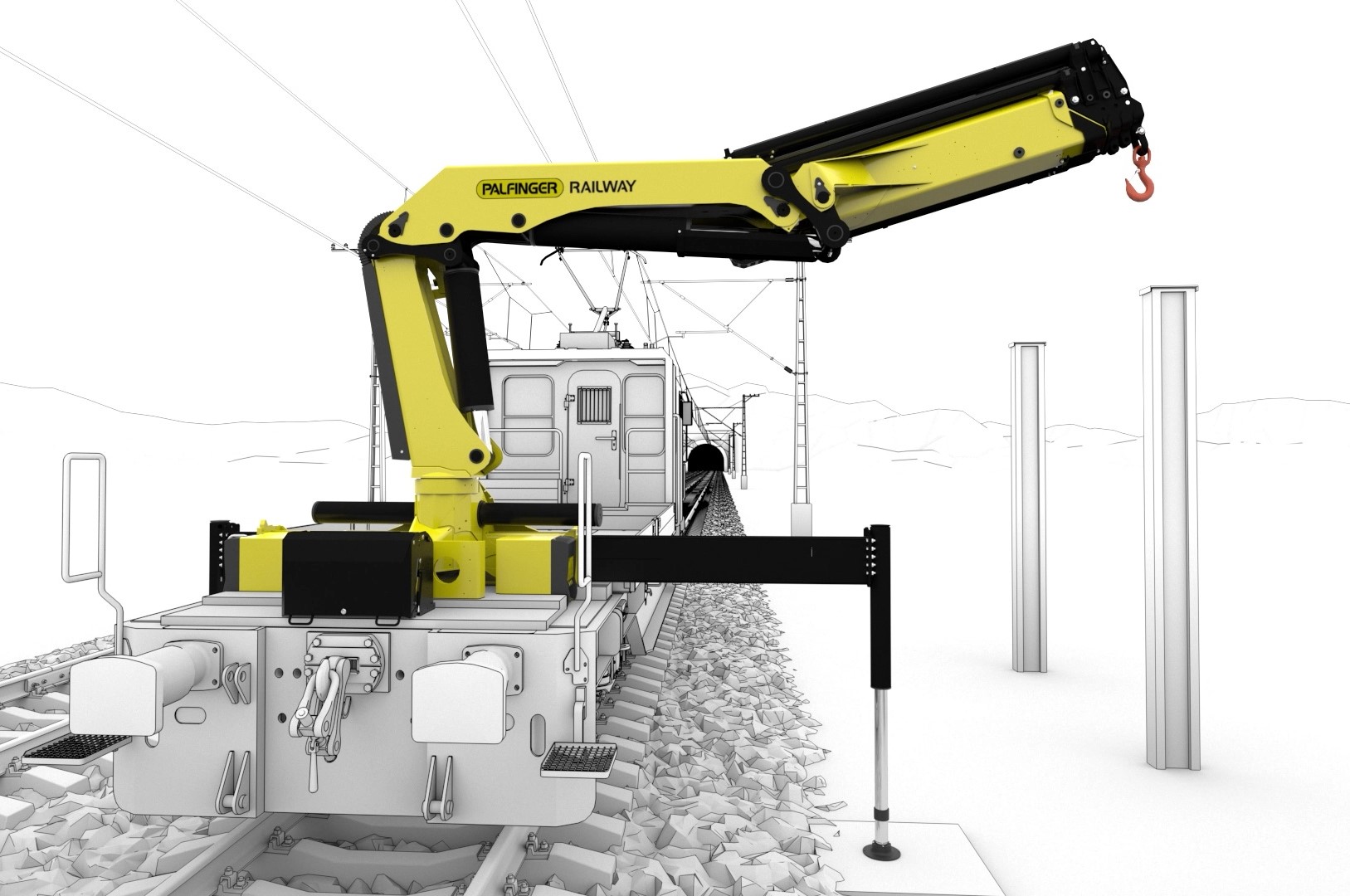

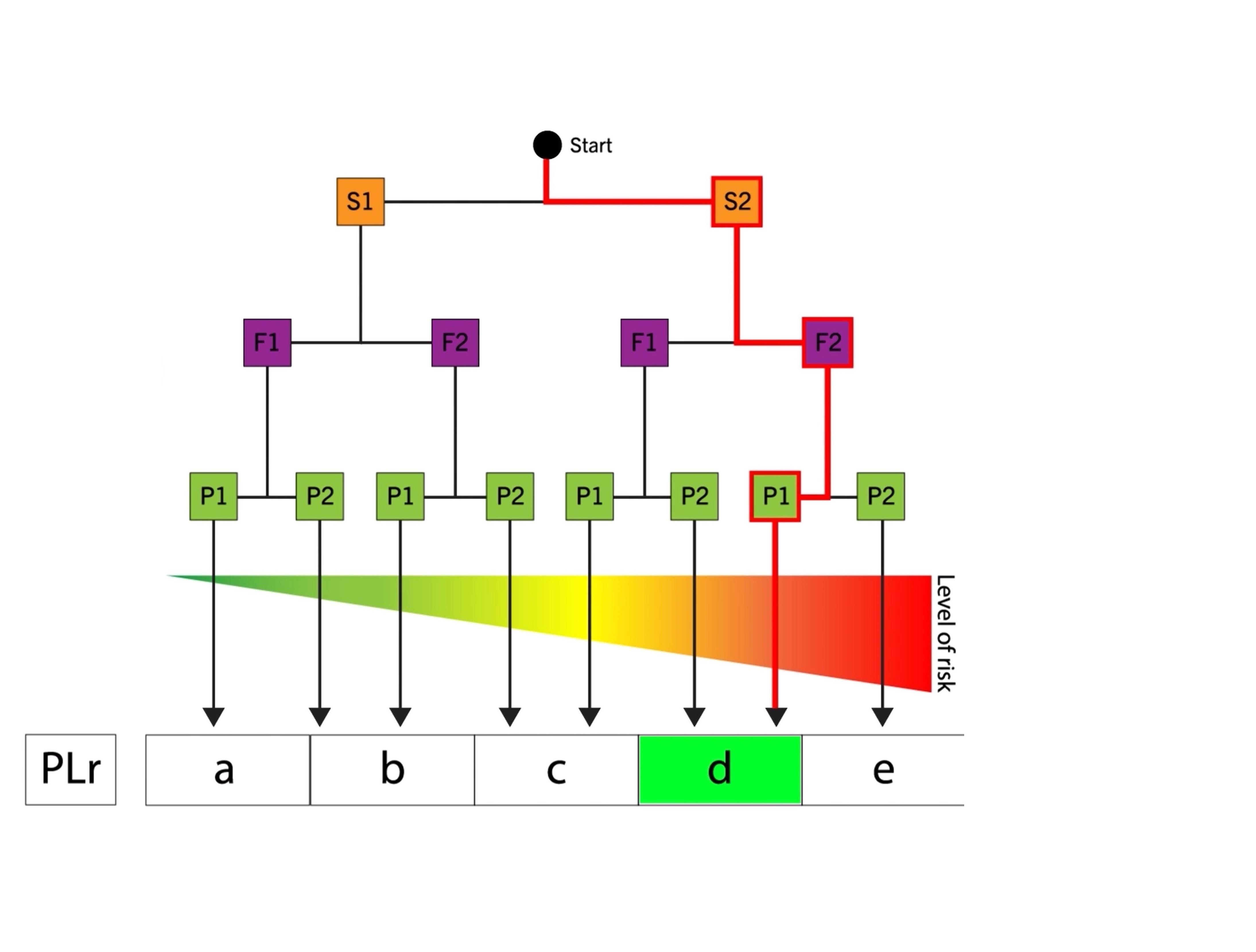

The innovative Basic Line opens up entirely new application possibilities for operators. With conformity to standards such as EN 14033 and the ability to implement safety functions according to Performance Level d (PL d) in accordance with EN 13849, the new Basic Line crane series is perfect for use in the railway sector. It precisely meets the specific operational safety regulations and occupational safety requirements in rail technology.

Emergency Control Stand

The freely positionable emergency control stand on the railway vehicle allows emergency operation in case of a failure of the radio remote control or power supply, from a secure

Height Limiter

Durch einen auf dem Notbedienstand angeordneten Schlüsselschalter, kann der Höhenbegrenzer aktiviert oder bei Arbeiten oberhalb der abgeschalteten und geerdeten Oberleitung auch deaktiviert werden. Auch dieses Sicherheitsmerkmal entspricht der EN ISO 13849 (PL d).

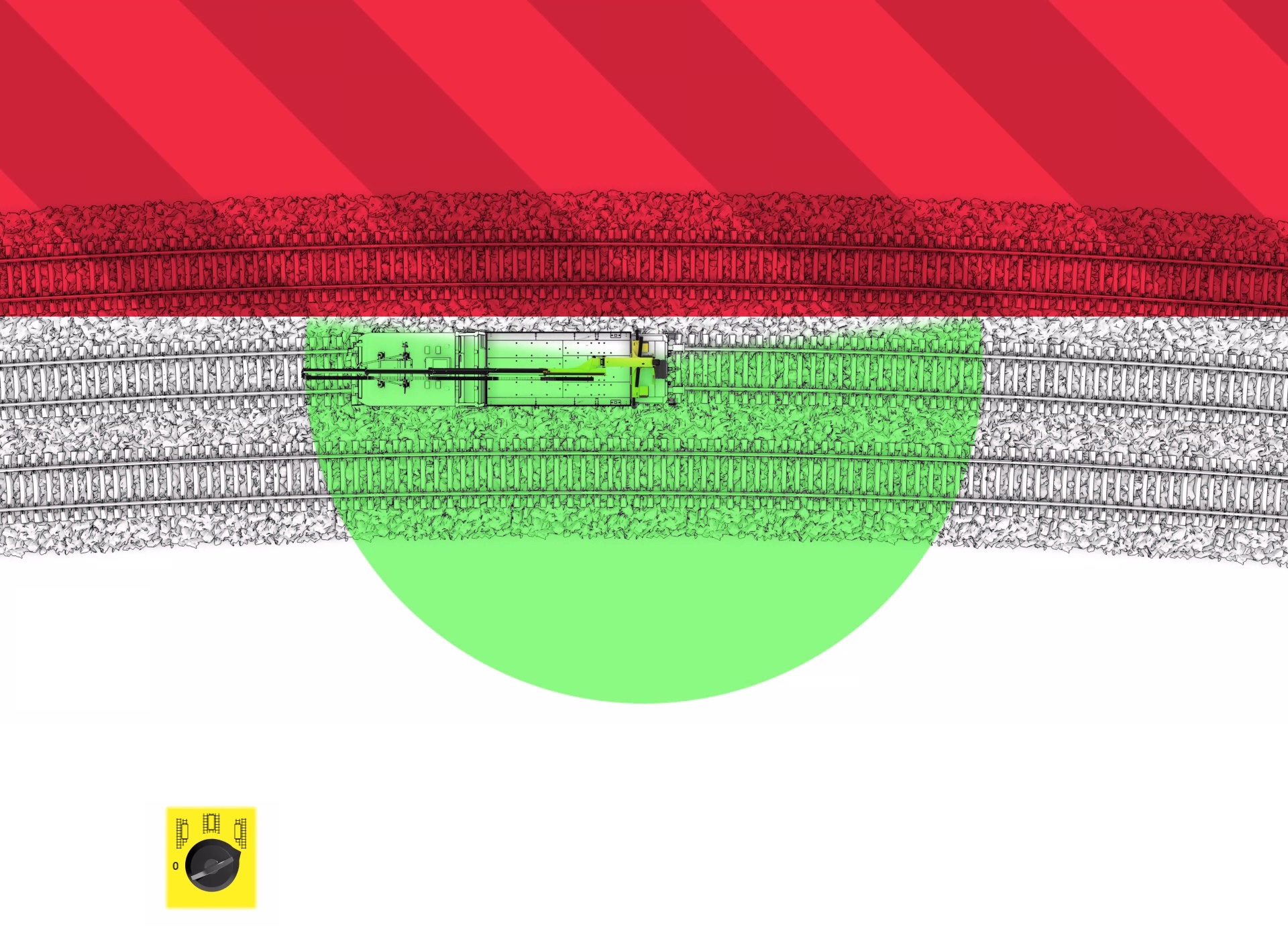

Slew Limiter

By using a key switch located on the freely positionable emergency control stand, the slew range can be selected according to the local and operational situation. This allows meeting operational safety requirements while minimizing restrictions of the working area. Complies with EN ISO 13849 (PL d).

Stability control

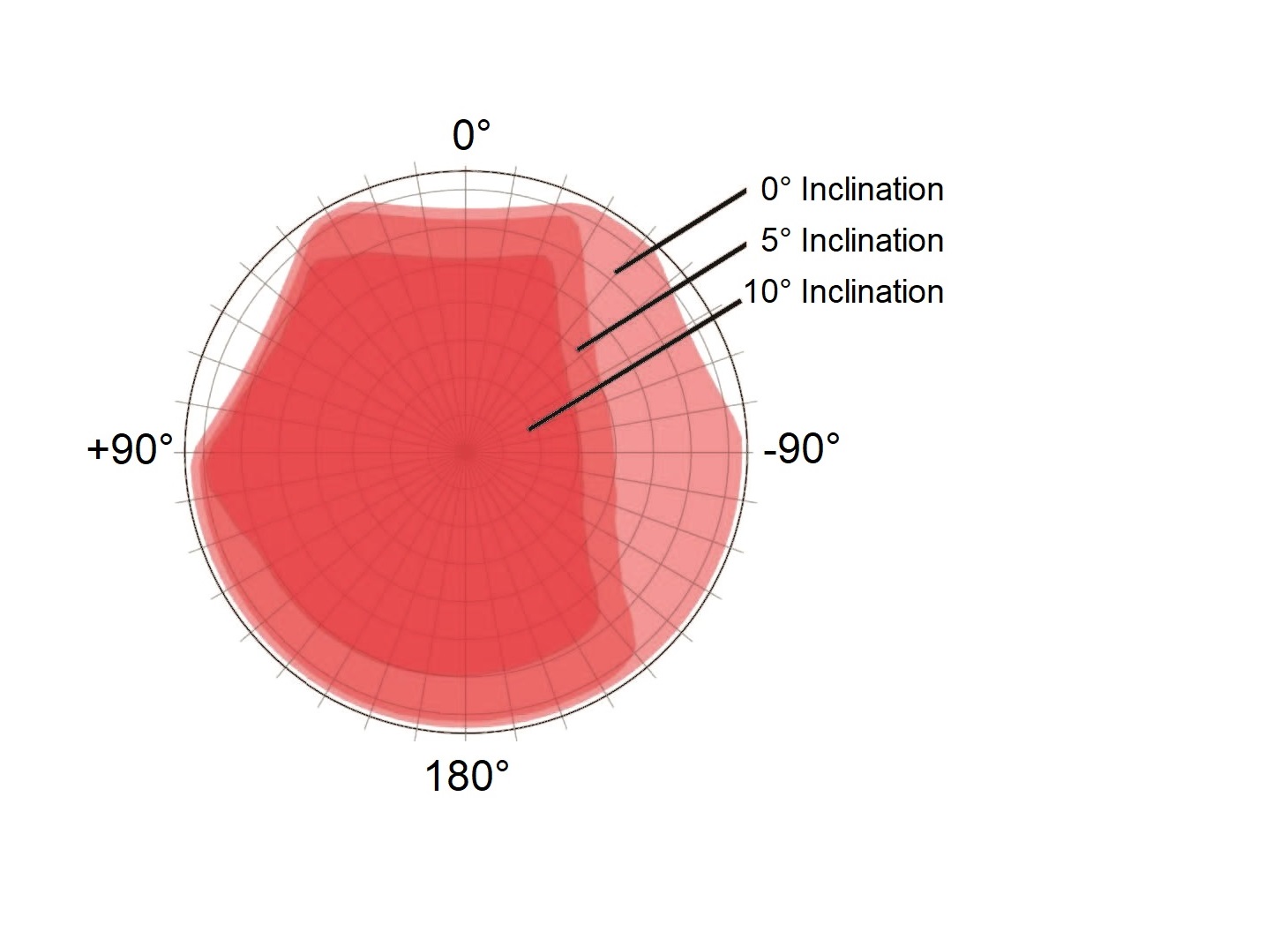

Thanks to the intelligent HPSC stability calculation, the crane's maximum load capacity, as well as the outrigger positions, slewing angle, and crane inclination, are continuously monitored. Considering the crane's inclination typically results in an impressive 80% increase in lifting capacities on straight, non-elevated track sections – and sometimes even more.

Working on Elevated Tracks

Due to vehicle dynamics, tracks are canted on curves. As a result, additional moments affect all crane components in canted areas. If the crane boom is in a horizontal position, the side load causes an excessive torsional moment on the crane column and slewing gear, while the crane outrigger in the upright position is subjected to an excessive side bending moment. So as not to structurally overload the crane in such extreme load situations or risk individual components breaking, the load capacity of the crane is electronically controlled while the crane inclination is taken into account at each moment of use.

Earthing

With the earthing of all components through highly flexible grounding cables, PALFINGER provides perfect protection against electric shocks. All components - from the base to the crane tip - are connected by 2x50mm² strong grounding cables. Transparent insulation material facilitates the inspection of grounding cables for breaks or damage caused by derived current (carbonization). Devices with a work basket are also equipped with grounding cables.

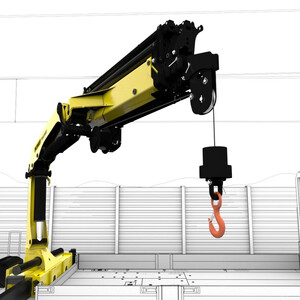

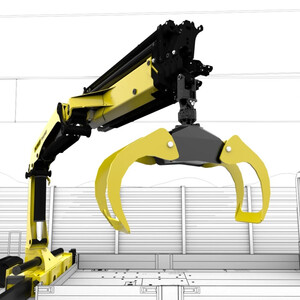

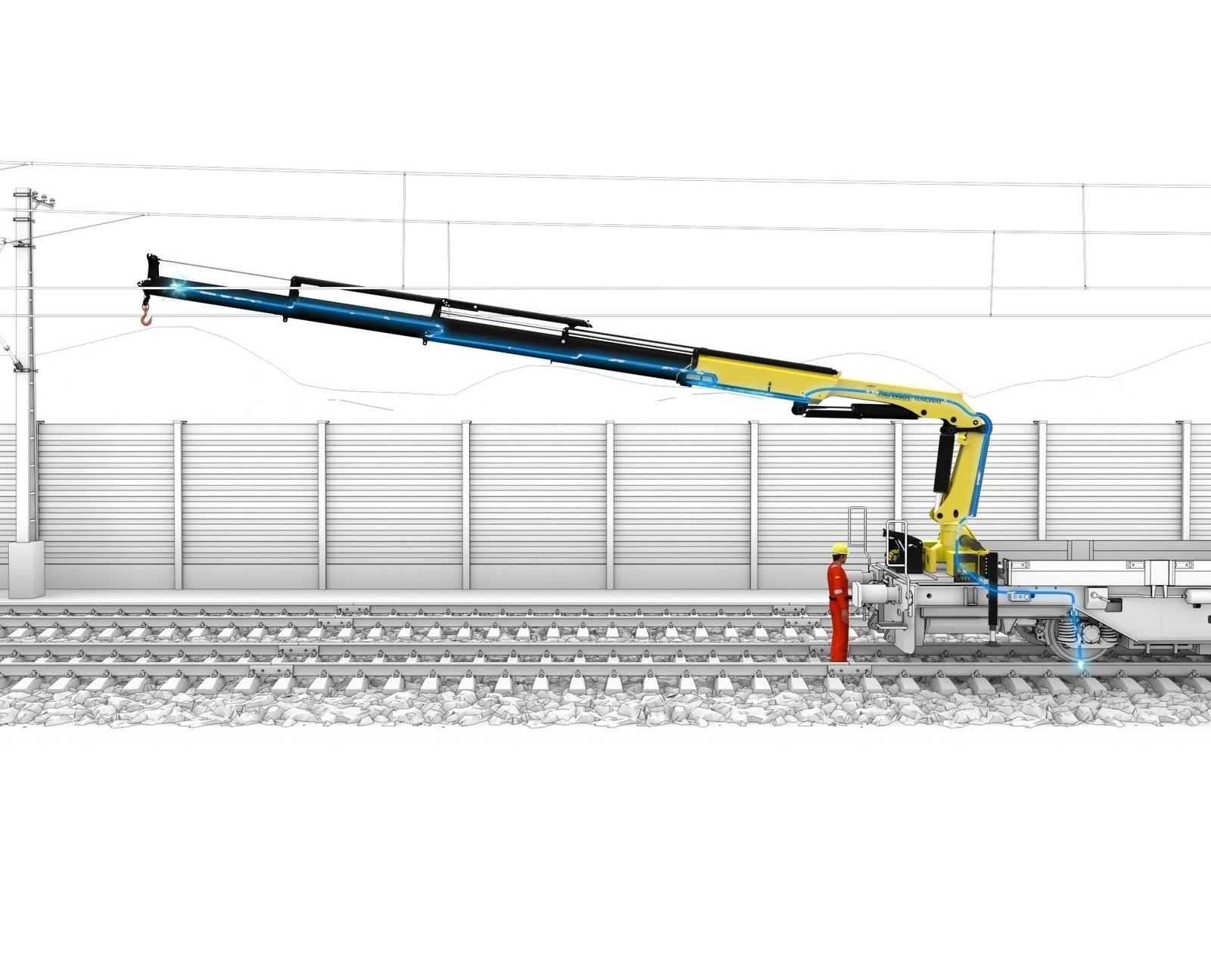

"Reverse” outer boom

The telescopic boom of the crane is equipped with a ‘reverse’ outer boom that can be raised upwards by 15 degrees (Fig. 5), thereby considerably increasing the respective working area naturally limited by the overhead line system and consequently the respective field of application as well. This enables more efficient installation and maintenance of noise barriers next to the tracks, for instance.

Linkage System

Thanks to the specially designed linkage system, the lifting moment can be maintained almost constant throughout the entire working range of the crane. Thus, work can be carried out under overhead lines without a noticeable loss of lifting force.

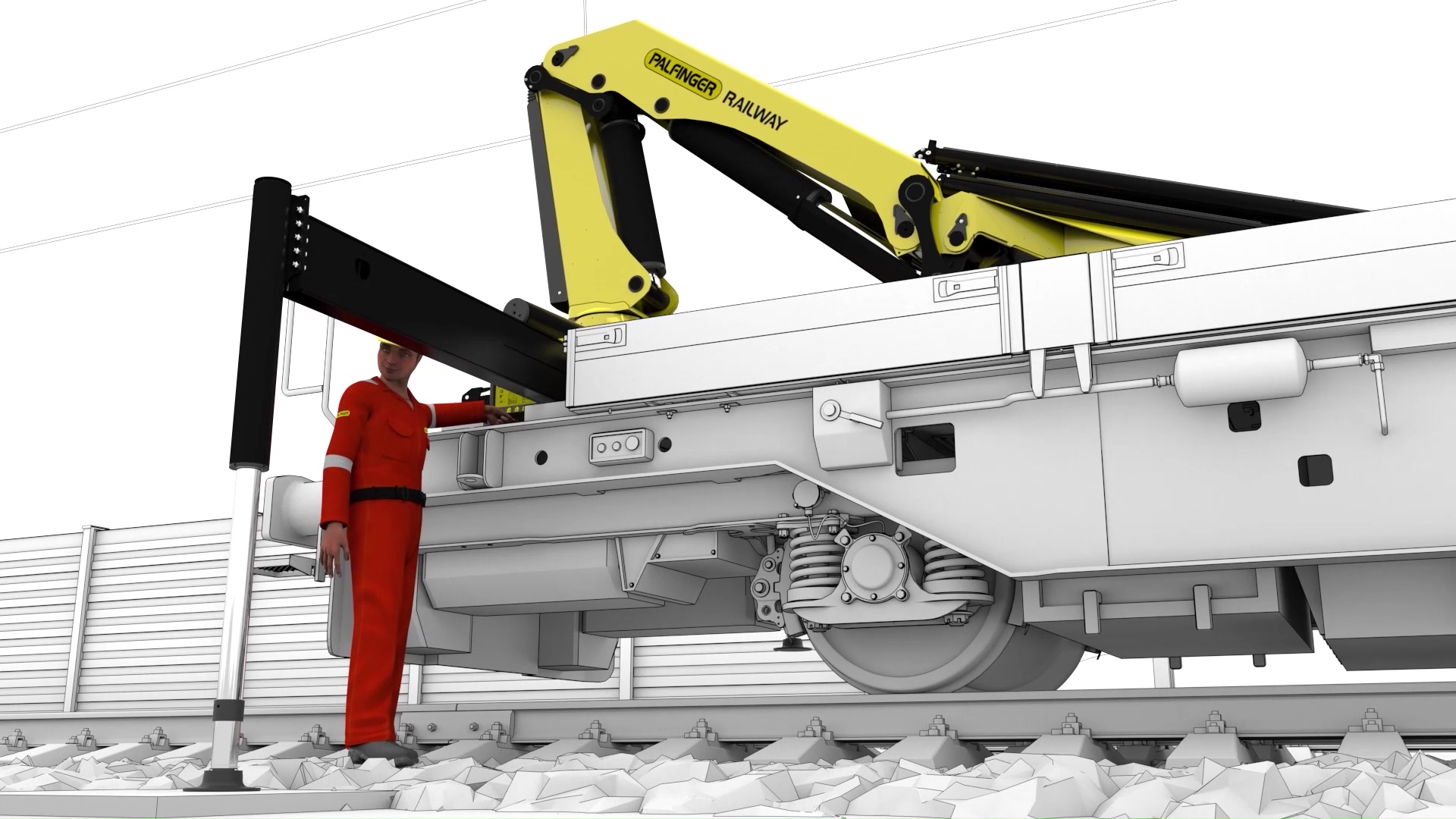

Radio Remote Control

All crane models in the Basic Line are controlled as standard via a radio remote control. This allows for a safe, ergonomic, and efficient operation of the crane, as the operator can be in close proximity to the load being transported. The operator can also take his position within the restricted working track in a secure area.

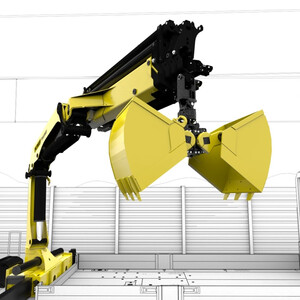

Hydraulic outriggers

Hydraulic outriggers are indispensable for railway cranes, as manually extendable outriggers are not only awkward to operate, but also can slip out unintentionally and uncontrollably owing to gravity when used on canted track. In a worst-case scenario, they could project into the structure gauge of a neighbouring operational track and thus present an operational risk to a railway

Performance Level according to ISO 13849-1 is PLd

The Paltronic crane control system, combined with the connected sensor system, achieves Performance Level PLd and meets the high safety standards of railway norms.

Brochures

You are currently on the PALFINGER United Kingdom page which shows the corresponding product assortment. We noticed that you come from a different location. Do you want to change to another PALFINGER country page?