Knuckle Boom Cranes

PALFINGER offers some of the most durable knuckle boom cranes in the industry. With a comprehensive range of models covering the entire range of working capacities, you can count on the right knuckle boom crane to match your needs. PALFINGER cranes are fast, efficient, precise, lightweight, and equipped with market-leading safety systems so that you can expect high performance in a variety of jobs. Excellent performance starts with a great foundation; all of our knuckle boom cranes are equipped with KTL Protection, superior hydraulics, and other unique features to PALFINGER.

FUNCTIONAL DESIGN

A good design must primarily fulfill its purpose, i.e. it should fulfill the function of the component the best way possible. Moreover, it must be possible to use it easily, ergonomically and economically. PALFINGER knows how to combine the functionality with individuality - through the use of new materials, shapes, colors and detailed solutions.

KTL — Cathodic Dip Painting

Innovative technology for surface coating is the foundation for durable and long-lasting surface protection—a unique KTL process with years of experience and environment-friendly energy consumption.

PALSOFT

Our goal is to provide our customers with product sales support, mounting, and service for dealers and customers.

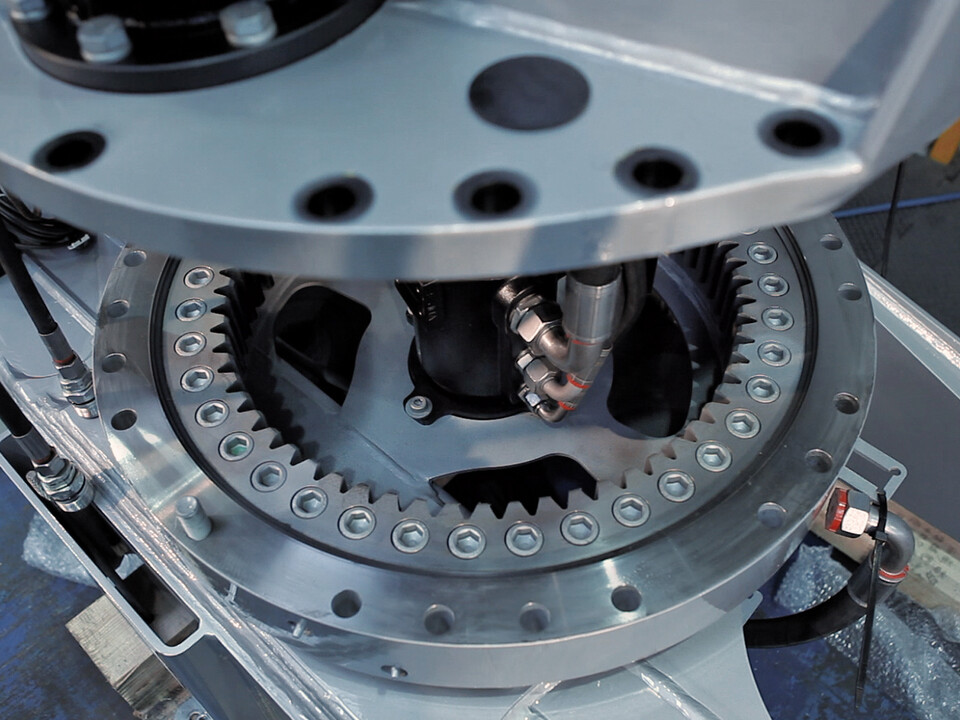

Turntable Bearing

The PALFINGER turntable bearing permits an unrestricted radius of action. The crane is rotated or 'slewed' using a gearbox and hydraulic motor rather than a rack and pinion system. All slewing mechanisms come as standard with a high-quality roller ball bearing.

How It Works

A hydraulic motor drives a pinion that meshes with a base-mounted high-quality roller ball bearing, rotating the crane. The gears are precision machined to minimize backlash between the gears. The roller ball bearing is made with very tight width, flatness, and perpendicularity tolerances. The matching surfaces on the base and the column are machined in a single clamping for the highest possible accuracy. On larger cranes, two identically sized slewing motors are set across from each other on the column. One motor is hydraulically preloaded against the other, eliminating all backlashes in the rotation system.

ACTIVE OSCILLATION SUPPRESSION

The patented PALFINGER ACTIVE OSCILLATION SUPPRESSION (AOS) system dampens the boom system of the crane, compensating for vibration and shock, even after a sudden stop of the lifting function. The result is a significant increase in saftey in crane operation for operator, loads and surrounding areas.

LOW MAINTENANCE EXTENSION SYSTEM

With the low maintenance extension system, PALFINGER leads the way in service-friendliness. The use of sliding elements made from special synthetic material and the highly dependable KTL cataphoretic dip painting means that the operator no longer needs to grease the boom system.

How It Works

The sliding elements are molded from special synthetic material and have self-lubricating properties. No further servicing is required after the first initial lubrication, in which food-grade grease is used. All other elements (slide rails, slide blocks, etc.) operate without grease. These elements have only a secondary function as sliding elements, primarily employed as adjustment and guiding elements. Special synthetic materials are also used for the paint to protect against corrosion.

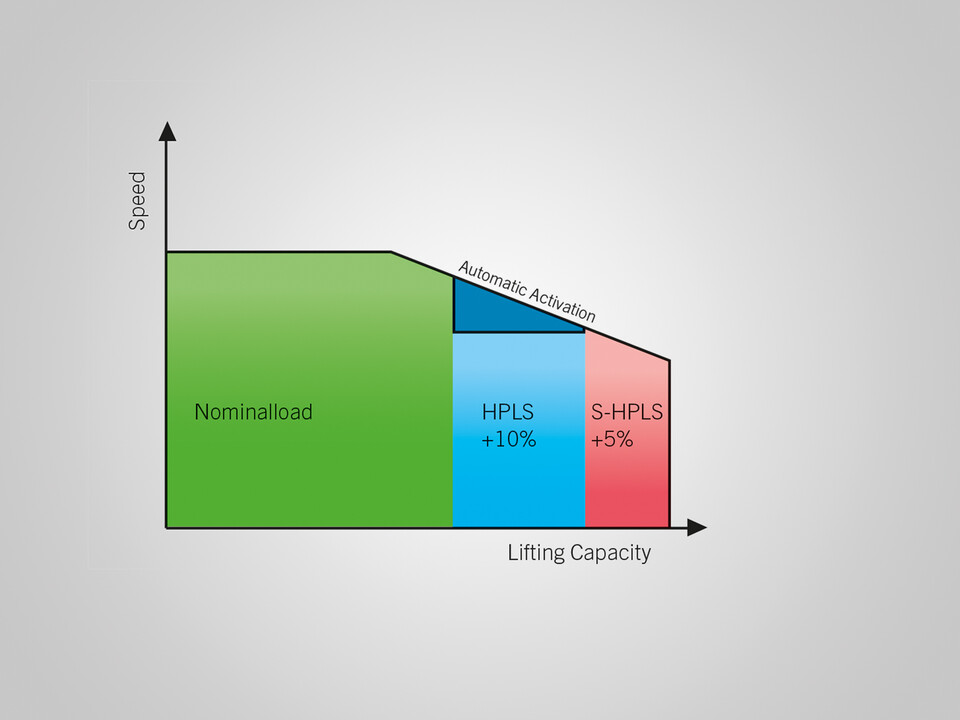

HPLS

The PALFINGER HIGH POWER LIFTING SYSTEM (E-HPLS or S-HPLS) increases the crane's capacity by up to 15% with reduced working speed. E-HPLS can be activated manually for the occasional manipulation of very heavy loads. S-HPLS is activated fully automatically for the SH crane series. There is continuous activation depending on the power required.

How It Works

If HPLS is activated, then the hydraulic pressure is increased electronically. That way, a higher payload can be achieved. At the same time, the speed is reduced by the electronic system.